You may have come across the terms "AN Fittings" and "AN Hose Assemblies" in your search for automotive aftermarket parts and performance components. But have you wondered what an AN fitting is? Perhaps you’ve got some AN fittings and are unsure about installing AN fittings. In this article, we’ll explain everything you need to know about AN fittings, including what you need to start, what you need to know beforehand, and the step-by-step instructions to ensure proper AN fitting installation.

Whether you’re looking for AN fittings for your vehicle, or unsure which ones will fit, just talk to our team of specialists and they’ll help you find what’s best. With a comprehensive range of AN fittings and hose assemblies to choose from, you’re in good hands at JEGS.

What Are AN Fittings?

AN Fittings, or Army-Navy Fittings are a type of fitting used to connect flexible and/or non-flexible hoses together in a variety of applications, including automotive use. The name AN Fittings came about during World War II, when the US Army and the US Navy agreed upon a joint standard size specification for fittings, to ease mechanical and engineering work across the two branches, and streamline production of spare parts for the war effort.

Today, AN fittings are used across a wide variety of segments, including automotive, aerospace, aeronautic, marine, industrial and of course, military. They are designed to perform under high stress environments and to extremely tight tolerances. AN fittings are designed for a variety of thread sizes, typically ranging from -4 to -24 in irregular steps.

We must remember that AN fittings use a standard 37-degree flare for their sealing surface. Hence, you cannot couple an AN fitting to a different flare-type fitting, as it will result in leaks. Instead, you’ve got to choose an appropriate adaptor in case you need to couple an AN fitting to another type. This can also be needed if you’re coupling different hose diameters together.

What You Will Need to Start

You’ll need a few things at hand to start building a hose assembly with AN fittings. These include:

- The relevant AN fititngs (male and female typically)

- Enough braided hose of a suitable size and specification

- Adaptors if required, as we’ve explained in the previous section

- Electrical tape

- A way to cut braided hose, such as a hacksaw, angle grinder or cutters

- Eye and ear protection if using power tools

- An assembly tool, such as the Koul Tool is helpful but not mandatory

- A sturdy vice, preferably mounted on a workbench

- An AN wrench or similar type

- A way to clean the inside of your assembled hose – pressurized air works great, as does brake cleaner in some applications

What to Know Beforehand

Want to know a few things about AN fittings? Here’s some prudent information.

- There are three common types of AN fittings. These are the crimp type, reusable hose ends, and the push-lock type.

- AN fittings typically use different colors for male and female types. Red and blue are the most common colors.

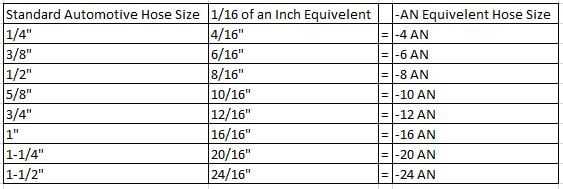

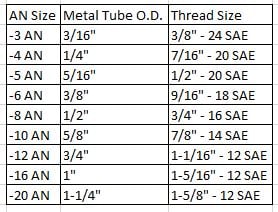

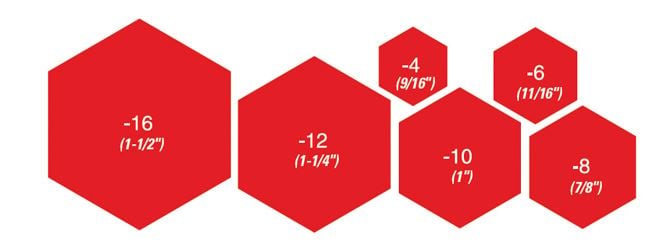

- You can use an AN Sizing chart to match a particular size of AN fitting to the type of hose that will match.

The below chart shows how AN size is determined. The number for the AN size is equivalent to how many sixteenths of an inch it is in size for inside diameter. For example, a -6 AN fitting means it is 6/16 of an inch, which simplifies to 3/8" for the fitting ID. Note that there are AN sizes missing from the chart that may be available (but with far less options to choose from than those on the chart) but are not part of the AN "standard" the performance automotive aftermarket follows. These include -5,-7,-9,-11,-13,-14,-15,-17,-18,-19,-21,-22,-23

Step by Step Instructions

- Firstly, you’ll need to measure how much braided hose you need for your chosen application. Once you’ve done that, it’s time to start cutting.

- Wait! Here’s a helpful tip for you before you start cutting. Wrap the end of the hose at the cutting point with electrical tape. This helps minimize the chance of frayed ends, which is a nightmare to deal with.

- Gently but firmly cut through the hose with your chosen cutting tool. If you’re using a power tool, ensure that you wear eye and ear protection.

- If you’re lucky, you’ll have a clean-cut hose. The unlucky among us will end up with varying degrees of frayed ends that are sharp and can easily pierce human flesh.

- This is where a Koul Tool can help, especially if you’re installing multiple lengths of hose, such as for upgrading your brake lines. Koul Tools can accommodate a range of AN sizes, and come with spacers and washers to help.

- Put the AN Hose End into the Koul Tool and use a spacer if required to ensure that the tool closes snugly.

- Now, place the Koul Tool with the AN Hose End in your vise and tighten it. Don’t over-tighten the vise, as the Koul Tool is made of plastic and can crack under excessive pressure.

- When the Koul Tool is firmly in the vice, take your braided hose and firmly push it in through the tapered end of the Koul Tool, rotating it clockwise as you push it in. A combination of rotating and pushing will be necessary. Ensure that the hose stops at the inside lip of the AN fitting, before the threaded end.

- Now, you can remove the Koul Tool and enjoy your braided hose with AN fitting sans any injuries from frayed ends.

- Wrap some tape at the end of the hose just before it enters the AN fitting. The reason for this is, as you screw on the corresponding AN fitting, you can visually observe if the hose gets pushed out, and detect any possibilities for leaks before installing and pressurizing the hose.

- Once you’re satisfied with your joints, just blast a combination of compressed air and brake cleaner down the hose. You’ll see quite a few shards of hose material come through. Now imagine these things going through the system once you’ve fitted the hose? That’s why we must always clean any hoses before using.

All Kinds of Fittings at JEGS

No matter what kind of fitting you’re looking for, we at JEGS are bound to have it in stock. Since 1960, when our founder Jeg Coughlin started the company, we’ve been providing an excellent range of products for automobile aficionados and enthusiasts. We pride ourselves on exceptional customer service, offering all applicable warranties, and ultra-competitive prices. With JEGS, you’re extremely unlikely to go wrong, and millions of satisfied customers over our six-plus decades of existence will testify to that. Why not join the community?