There are many components involved with carburetors and fuel systems. Understanding how to adjust and tune a carburetor along with fuel system maintenance will help to resolve issues quickly and provide longer fuel system life with better engine performance. Below are answers to the most common questions about fuel system maintenance as well as carburetor tuning and adjustment:

Carburetor Adjustment And How to Tune a Carburetor

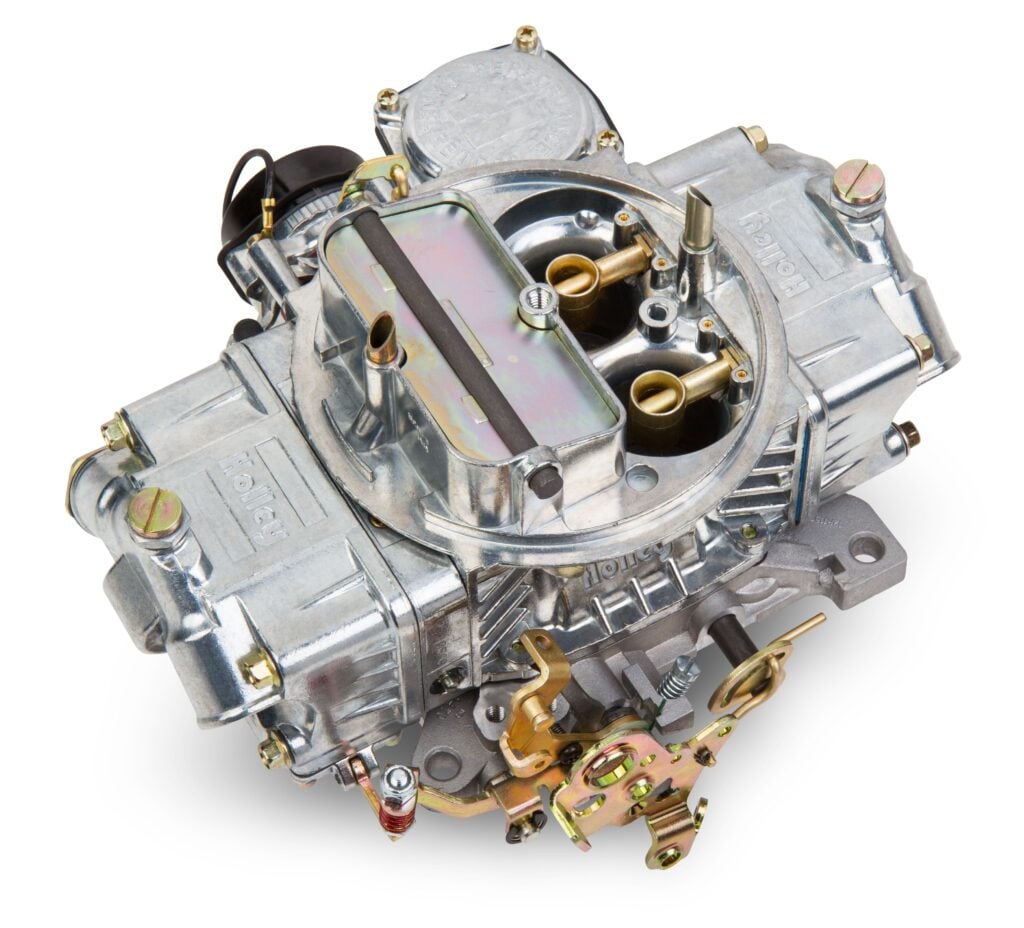

Tuning a carburetor mainly refers to making part changes that affect the amount of fuel introduced into the engine. These changes can be performed with ease provided you understand how the specific carburetor being used functions. Because there are many different types of carbs, consulting the owner’s manual for the specific carburetor you are working on is the best option for proper tuning and carburetor adjustment. However, we will cover, in a general overview, the two most popular types of carburetors from Holley (including Holley-style versions from other manufacturers) and Edelbrock. To prepare for the proper tuning of a carburetor, confirm that the proper fuel pressure is reaching the carburetor with a gauge. Also, confirm that the ignition timing for the engine is correct. Next, start the engine and allow it to warm up. Once warmed up, check the vacuum at idle (confirm your engine’s correct idle speed, typically between 800-1000 rpms) using a port either from the intake or below the throttle blades on the carburetor. Record or memorize the vacuum reading.

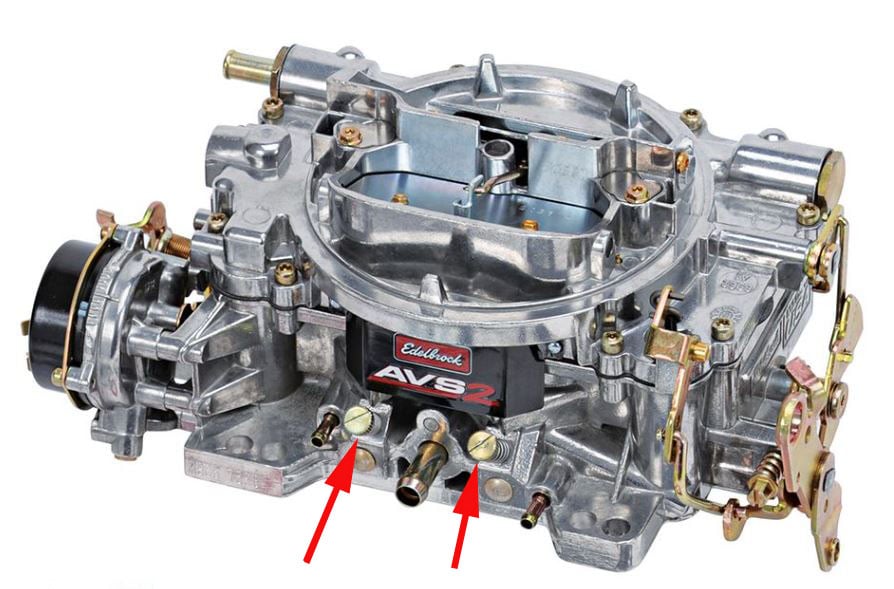

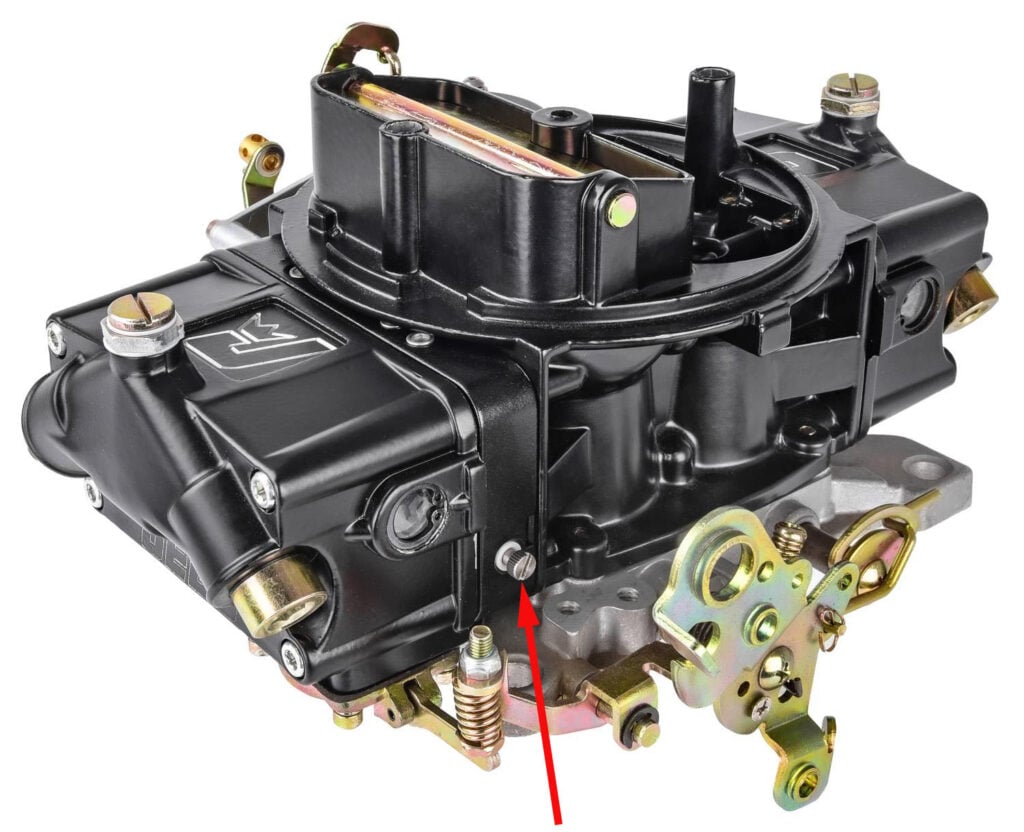

Next is idle mixture screw adjustment. On Holley carbs, they are located on the metering blocks on either side of the main body; typically, there are either 2 or 4 screws. On Edelbrock carburetors, these screws are on the front side. When adjusting a carburetor idle screw, the goal is to adjust it to the “lean-best” setting. To do this, with the engine warmed up and at idle, and using a vacuum gauge connected to engine vacuum (use a carburetor vacuum fitting below the carburetor throttle blades), turn one of the screws clockwise until you get the highest vacuum reading on your gauge. When you reach the highest vacuum reading, turn it counter-clockwise just a slight amount. If turning the screw clockwise does not increase vacuum, turn it counter-clockwise to ensure the screw is not set too far one way. Next, repeat the same process to the other idle mixture screw. Since changing one idle mixture screw affects the other, go back to the previous idle mixture screw and adjust it. This process needs to continue until both screws are adjusted to maximum vacuum reading. If turning the idle screw doesn't change vacuum, the passage way to it is blocked and needs cleaned with either air pressure or proper solvent. Record the engine vacuum reading for the next step. The idle screw adjustment process reduces the amount of unnecessary fuel at idle and prevents spark plug fouling as well as improving engine fuel efficiency.

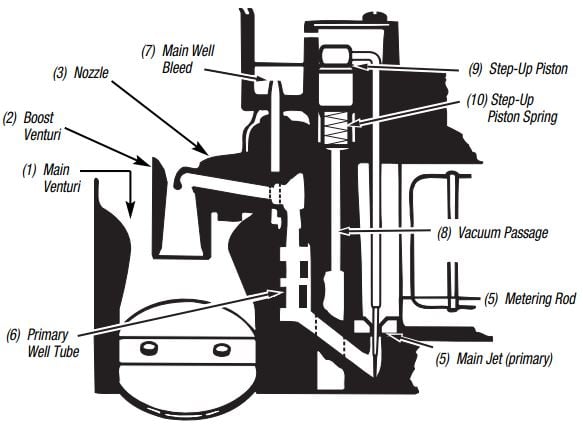

Then, taking your vacuum reading, you need to confirm that either the step-up springs (in Edelbrock carburetors) or the power valve (in Holley-style carburetors) are properly matched to engine vacuum. To do this, take the idle vacuum reading and divide it by two. The result is what you need to match with the power valve or step up springs. If you are between 2 options, select the higher number. The step-up springs in an Edelbrock carburetor pull the tapered metering rods out of the jet holes when there is less vacuum than the spring is rated for, providing metered fuel when the vehicle accelerates. The Holley power valve helps enrichen the fuel mixture in a different way, but below its vacuum rating. This is accomplished with a rubber diaphragm that is moved, depending on vacuum, opening or closing the fuel path. More information on proper tuning and operation is available in your carburetor owner’s manual.

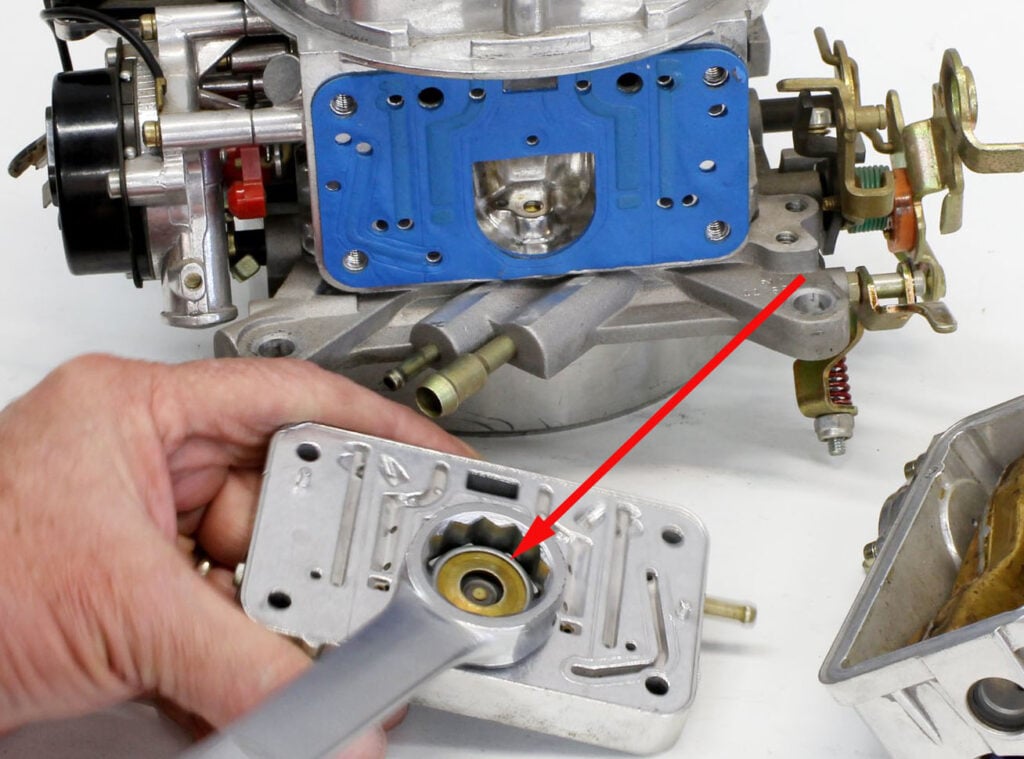

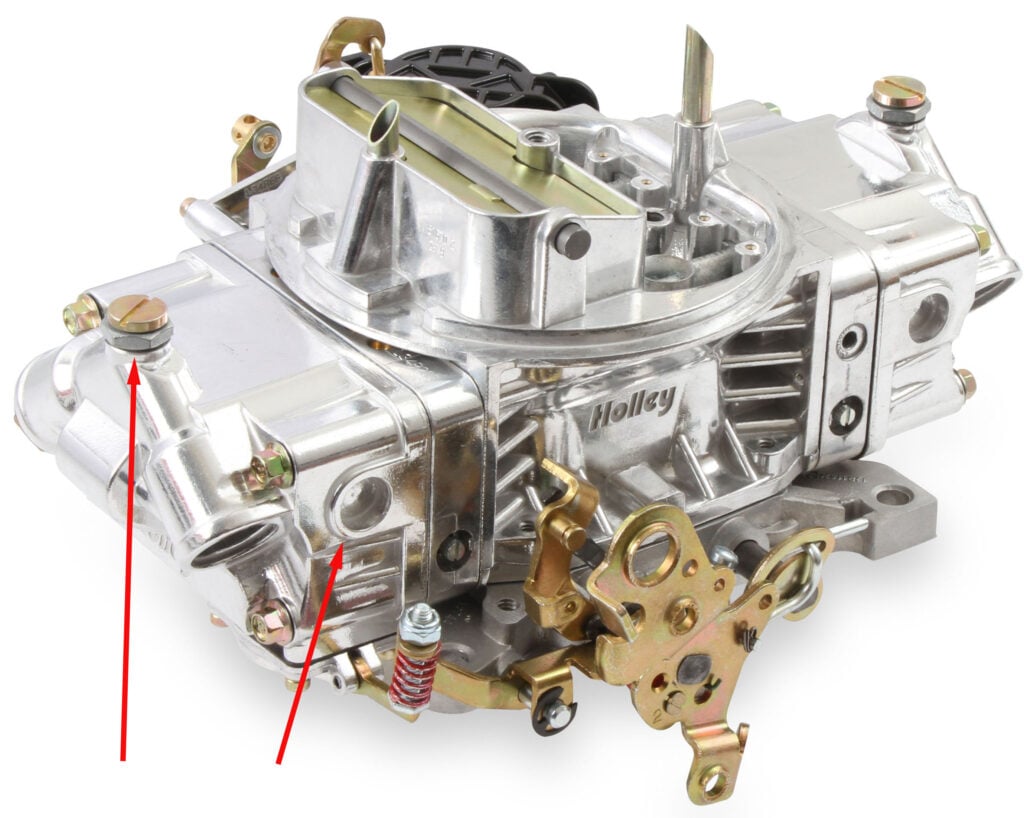

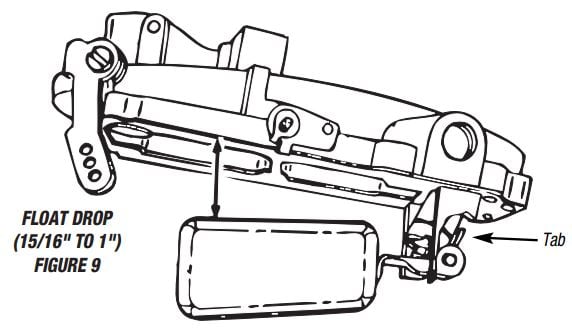

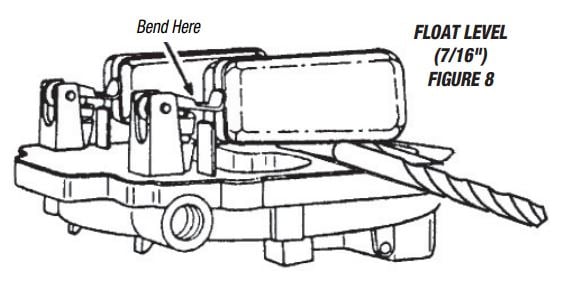

Holley adjustable vacuum secondary carbs also follow a similar procedure for the correct vacuum secondary diaphragm spring and can be changed as necessary. Edelbrock AVS2 carburetors use set screws to adjust vacuum secondaries (Edelbrock Performer carbs are not adjustable and have to be modified). Another adjustment for both carburetor versions is the float. On Holley adjustable float carbs, this is changed externally by loosening the nut on top of the fuel bowl and turning the screw until fuel just reaches the bottom of the sight plug hole (plug removal required). The proper way to make this adjustment is with the engine running and a proper container to collect any leaking fuel. The nut is then retightened and the sight plug is reinstalled. This prevents flooding from too much fuel as well as fuel starvation due to too low of a fuel level in the bowl. On Edelbrock carbs, the top of the carburetor needs removed to adjust the floats. Once removed, compare how low the floats hang when holding the top upright to the specifications in the owner’s manual. Then turn the top upside down and measure the float distance to the carb top and compare the carburetor specifications. Adjustment is made by gently bending the float limiter tabs.

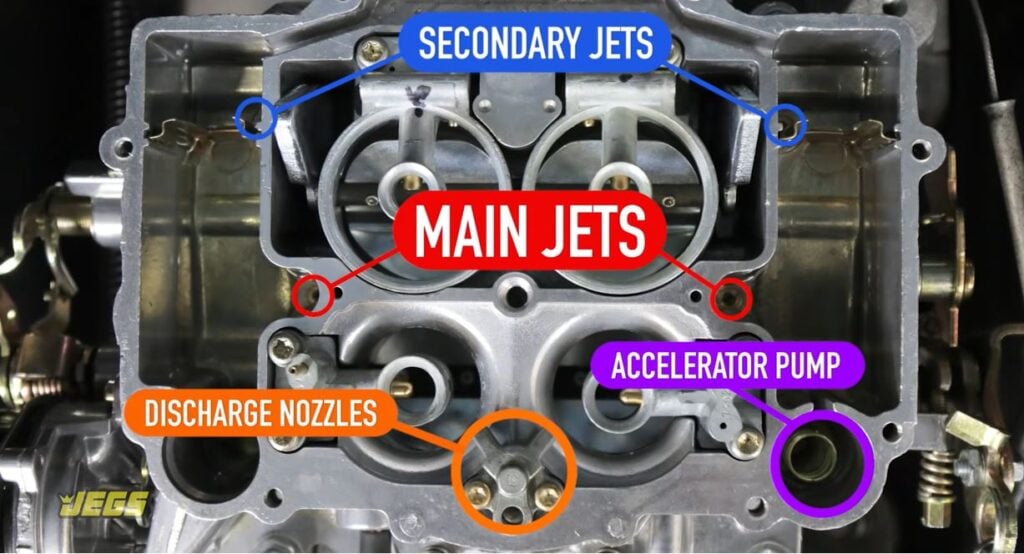

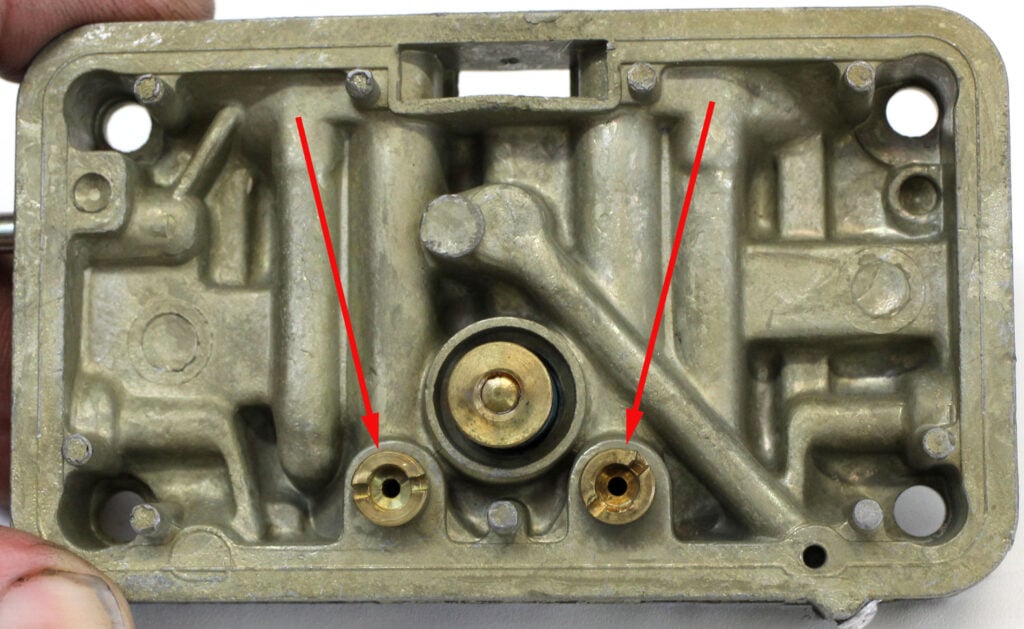

Another important carburetor turning step is the carburetor jetting. Access to inside the fuel bowls (Edelbrock) or to the metering blocks/main body ( Holley) is required to make changes. If the carburetor is providing too much or not enough fuel during idle, part throttle, or wide open throttle, after all of the previous tuning has been completed, the jets mostly likely need changed. Use the instructions in the owner’s manual on proper selection. Edelbrock uses a specific combination for the primary jets with metering rods as they work together from idle to part throttle, located in their instructions. If a fuel adjustment is needed for the secondaries on either carb, jet replacement is required (or metering plate for single metering block Holley carbs). There are additional tuning and adjustment options that may be required to further improve performance. The carburetor owner’s manual will help you with those additional steps.

Where to Buy Carburetor Adjustment Tool

JEGS offers a selection of carburetor adjustment tools for many 1990 and older GM (example Quadra-jet) and Chrysler carbs.

What Maintenance do Technicians Perform to Fuel Systems?

There are several different types of fuel system maintenance that technicians can perform on a fuel system, depending on the vehicle fuel system being serviced. If the vehicle has an external fuel filter, it is typically replaced. A fuel system cleaner additive may be added to the fuel tank as well to clean from the tank to the exhaust valves chemically. Fuel pressure is also tested. More involved maintenance includes cleaning carbon deposits from the throttle body and intake manifold runners as well as fuel injectors. Any components that are tested, inspected, and confirmed worn or defective will be replaced at this time.

How to Tell if There's Water in an Automotive Fuel System

When attempting to mix water with gasoline, water will separate and sink to the bottom of the fuel tank since it is denser than gas. If the fuel tank has a drain, it could be opened and with a small test tube and a sample from the gas tank could be collected to see if there is water and gas separation. However, most fuel tanks do not have a drain. If the vehicle does not have an anti-siphon fuel tank filler neck, a sample can be siphoned from the bottom of the tank to check for water. The only other option is to remove the tank in order to open the access cover and test the gas. Typical symptoms of water being present in the fuel system include starting and idling problems, lower fuel efficiency and slower acceleration, as well as hesitation while driving. These symptoms can be more prevalent in below freezing temperatures as the water in the fuel crystalizes and freezes. A simple solution to combat and improve performance if water is suspected is fuel system water remover & antifreeze. This product is added to a full tank of gas. Time is needed for it to work its way through the complete fuel system, however if water is the cause of the poor performance, this product will resolve it. If water contamination is persistent in your vehicle’s fuel system, you can add a fuel filter / water separator to help control impurities.

Can't Find the Carburetor And Fuel System Components You Are Looking For?

A JEGS expert is ready to answer your questions and help you find the fuel system and carb components that you require for your specific application.