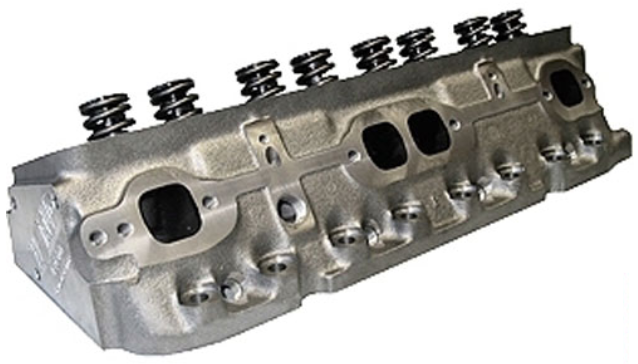

Cylinder heads are a very important engine component, controlling intake and exhaust flow as well as performance. There are many factors and steps involved in selecting, removing, rebuilding and purchasing a cylinder head. But what is a cylinder head exactly? It's crucial to understand the definition, along with terminology that's associated with the different types of cylinder heads on the market. This will help you know how to choose cylinder heads that are right for different applications.

Internal combustion engines are, simply said, air pumps. The more air you pump into an engine, the more air/fuel you can burn, and the more power you can make. Building horsepower is not quite as simple as that, but it's the basic concept. So what is a cylinder head? The cylinder head is the main component that flows air/fuel in and exhaust gases out. Needless to say, the cylinder head is a major component in building horsepower and torque. Because the shape and size of the combustion chamber affects so much of an engine's operation, you have to choose the appropriate part, not just the one with the best peak numbers. Understanding cylinder head terminology and ultimate affects will help when choosing cylinder heads for your application. Your goal should be to choose the best heads. Going with the BIGGEST heads is not always best. Read on to learn how to choose cylinder heads that are right for you.

What Does A Cylinder Head Do?

A cylinder head helps control the direction and flow of incoming air and fuel as well as outgoing exhaust from an engine. It houses part of the valvetrain, which includes the valves, valve springs, rocker arms and pushrods. The camshaft controls how long and how far the valves in heads are open within the cylinder heads.

Types of Cylinder Heads

There are many different types of cylinder heads. Most are made from cast iron or aluminum. Some are designed specifically for marine applications or for use with engines that have emission control connections. Stock replacement heads work for daily-driven vehicles and are designed with fuel economy and standard performance in mind. Performance and race cylinder heads are designed for maximum flow to provide increased horsepower and torque. Some cylinder heads are designed for overhead camshafts in addition to overhead valve configuration, while others accomplish valve opening and closing differently based on the manufacturer's design.

Cast Iron Cylinder Heads

OEM cylinder heads are often cast iron which offers durability and a lower cost to produce and manufacture. Cast iron types of cylinder heads, as you would expect, are also heavy. For almost all applications, lighter is better. Drag cars in particular benefit from lighter heads to help launch, and road course/circle track cars benefit from better weight distribution. Another downfall of cast iron is it lacks the ability to dissipate heat. Aluminum dissipates heat better, which will allow for a higher compression ratio without detonation. Cast iron will provide a good option for the budget-minded builder. Performance options are available for cast iron heads that include larger valves and increased flow designs, but should be limited to lower compression street cars for the most part.

Aluminum Cylinder Heads

Aluminum, as stated above, provides a sizable weight advantage over cast iron. Since most performance vehicles benefit from the weight savings of aluminum, many drivers upgrade to these types of cylinder heads. There are many companies casting high-performance aluminum cylinder heads for street and track performance. Aluminum alloys are now much more durable and resistant to warping than they were years ago, and material problems are minimal. Most manufacturers offer different configurations of the same head, depending on your needs. Most offer from a raw or bare casting to provide the end user a complete, or assembled, head built to their specs which they can simply take out of the box and bolt on.

How To Remove A Cylinder Head

To remove a cylinder head, first disassemble any parts that are in the way. This may include belt-driven accessory brackets, emission components, air intake ducting or hoses. Next, remove the intake and exhaust manifolds or headers as well as the distributor and ignition components. Then, remove the valve covers, rocker arms and pushrods. Finally, remove the cylinder head by taking out its bolts. Be sure to clean the block mounting surface after removal and cover or protect any internal engine components from parts or debris to prevent accidental damage during start up.

How To Clean A Cylinder Head

There are multiple ways to clean different types of cylinder heads. Using an engine parts cleaner and a brush will do a large part of the cleaning. Care has to be taken if cleaning around the valve guides, intake, exhaust and valve cover gasket sealing surfaces to avoid damage or possible leaks upon reassembly. To remove the gaskets, a gasket scraper and a gasket remover spray will help to get stubborn material dislodged from the head. Sensitive areas will require a softer brush. If additional cleaning is required, seek the help of a local machine shop who can also properly check all the sealing surfaces.

How Much Does It Cost To Replace A Cylinder Head?

It depends on the types of cylinder heads you're considering for replacement. Cylinder heads can cost anywhere from under $200 for a remanufactured stock specification cast iron head to over $6,000 for an all-out, race-prepped aluminum cylinder head. The labor to replace a cylinder head depends on the application and the repair shop doing the replacement. Understanding how to choose cylinder heads that are appropriate for each application will help you avoid overpaying.

How to Rebuild Cylinder Heads

Rebuilding cylinder heads requires the removal of all of the components. This includes the rocker arms, rocker arm studs, guide plates, valve springs, retainers, keepers, shims, valve seals and valves. What will be left are the bare cylinder heads with installed valve guides. Next, clean the cylinder heads. If attempting to reuse the valve springs, use a spring pressure tester to confirm they meet factory specifications. Inspect the retainers and keepers for any excessive wear or damage and replace as necessary. The cylinder heads then need to be taken to a machine shop to be inspected and machined if any surfaces need to be prepped to seal properly. They can also check the valve guides to confirm if they need to be replaced or not. If you plan to reuse the valves, the machine shop can check them to make sure they are reusable — they can also machine them and the cylinder head surface to match. Last, once you receive the cylinder heads back, assemble the valves and springs with the valve stem seals and reassemble the rest of the drivetrain after assembly with the engine.

Terms You Should Know When Choosing Cylinder Heads

To address choosing cylinder heads in an overview, we need to speak in relative terms. Smaller cubic inch engines will typically require smaller measurements on all components when compared to a larger cubic inch engine. Valves, for example, are usually smaller for small blocks vs. big blocks. Engine displacement works hand in hand with the cylinder head specifications and individual component size. Simply said, as the capacity of the engine increases, the need for higher volumes of air in and out of the engine will increase proportionally.

- Combustion Chamber - The size of the combustion chamber partially determines engine compression. A larger combustion chamber makes the cylinder volume larger. Assuming you don't change anything else in your engine setup, swapping cylinder heads with a smaller combustion chamber will increase compression. Because you're compressing the same amount of air into a smaller place, the overall compression ratio goes up. Adding a head with a larger cylinder head combustion chamber would yield the opposite — less compression.

- Intake Port Shape & Size - Cylinder heads have intake port runners where fuel and air flows through to get to the cylinder. On a 16 valve V8 engine, each cylinder head has 4 intake and 4 exhaust ports. Each port matches up to an intake or exhaust valve. The size and shape of the intake ports affect the torque and horsepower curve. Larger ports can flow more. Plus, you usually try to match your intake port type on your cylinder head to an intake manifold with similarly shaped ports. Air and fuel flow through the intake into the intake ports on the heads. Restrictions, or misaligned ports, at this joint will alter the flow of air and fuel and may affect performance. One of the major concerns is that you get a good seal between the heads and intake manifold to avoid coolant leaks. There are basically 2 types of ports. Oval port heads are basically oval shaped. The shape is not an exact oval. Rectangular shaped heads are also not an exact rectangle shape. They are mostly rectangular with the corners usually rounded off.

- Intake Runner Volume - When installing and choosing cylinder heads, note that a larger intake runner volume allows more air and fuel to flow through it. However, the larger "tunnel" will slow the velocity of gases moving through it. Smaller intake runners would speed up the flow of gases through the cylinder head and increase throttle response and torque. If you want the magic combination: A head with good flow and air velocity would give you the best of both worlds. The bigger your engine displacement, the larger your cylinder head intake runners generally need to be. The bigger your intake runners are, the higher the power band is pushed. If you want to build power for the street, huge intake runners will build big horsepower at NON-streetable RPMs. You're better off with smaller intake runners which help build power at lower RPMs.

- Exhaust Port Shape & Size - Exhaust port shape is less important than intake port shape. As long as your headers or exhaust manifolds are bigger than the port on the head, and the gasket seals well, the gas will exit as it should. Where intake runners on heads have to line up more precisely with the intake manifold for good flow and coolant openings must seal, the exhaust port shape is less critical.

- Intake Valves - Intake valves are typically larger than exhaust valves. 2.02-inch diameter intake valves are common small block valves. As you would expect, the larger the valve, the more air and fuel can flow through the valve (valve lift will also affect the volume of air/fuel flow). Intake valves are larger than exhaust valves because the piston is moving away from it, creating a vacuum to pull air and fuel into the cylinder. Pulling air and fuel in is not as efficient as pushing air out of the engine, as is the case with the exhaust stroke pushing exhaust gases out of the cylinder.

- Exhaust Valves - Exhaust valves are smaller than intake valves. 1.60-inch diameter exhaust valves are common on SBC engines. Like the intake valve, the larger it is the more it will flow. Cylinders are only so wide, and you have to fit an intake and exhaust valve plus a spark plug in each cylinder. There is a point at which a 2-valve engine maxes out the area to fit larger valves. It won't physically fit in the head over the cylinder.

How to Choose Cylinder Heads

When choosing cylinder heads, first establish the application for the engine and vehicle that will be used. Whether for a daily-driver, a mostly-strip/some-street, mostly-street/some-strip or drag-race-only application, how you intend to use the engine will determine how to choose cylinder heads that are appropriate. The cylinder heads you choose should match the camshaft specifications to maximize efficiency and performance. Since the camshaft controls how long the valves are open as well as how far they are open, the cylinder head needs to align with the camshaft in terms of valve size, intake and exhaust runner volume as well as flow. As mentioned, cylinder heads are typically available in cast iron and aluminum. Aluminum heads are more expensive. However, they provide the benefit of weight savings as well as the ability to run pump gas with higher compression for street applications. Most performance cylinder heads are also made from aluminum.

When You're Choosing Cylinder Heads, Let JEGS Help

So, what is a cylinder head? It's an important factor to consider when upgrading your vehicle. Reading this page and understanding the above terms will hopefully help lead you in the right direction when you're learning how to choose cylinder heads. The best suggestion overall is to stay conservative. For example, a cylinder head with a large intake runner has no business on a low-RPM street application. This will result in a sizable torque loss, thus not meeting the needs of your intended purpose nor of the engine. Be realistic, choose the head that matches what you are doing and, if you are selecting an assembled head, make sure the springs included match your camshaft selection.

If you read and understand the topics included in this article, we are confident that you will at least make an informed decision. If you still have trouble choosing cylinder heads, the JEGS tech line is available. You can also reach us by our JEGS Ask-A-Tech service where we will be glad to help you choose. Shop JEGS today for all the different types of cylinder heads you need.