How To Measure Wheel Size

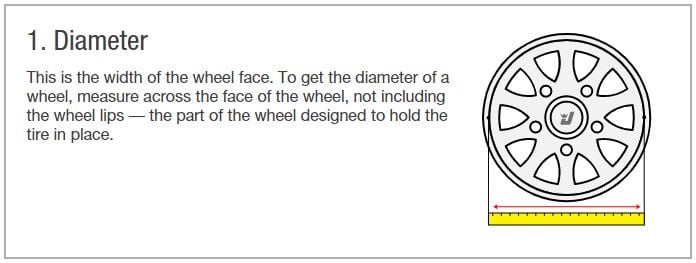

Wheels or "rims" refer to the metal vehicle part that connects the rubber tire to the vehicle hub or axle, allowing it to roll. It is important to understand how to measure a wheel when making changes in size from factory specifications. The wheel diameter refers to the measurement across the face of the wheel. To measure wheel diameter, start slightly inward from the edge or lip of the wheel with a tape measure. Then bring the measurement across the center of the wheel to the opposite edge of the rim. It’s important to not include the wheel lip on both sides into your measurement. This is because the lip is slightly oversized to allow the tire to seal against the inside of the wheel. Typical wheel diameters include 14”, 15”, 16”, 16.5”, 17”, 18”, 19”, 20”, 21”, 22”, and higher.

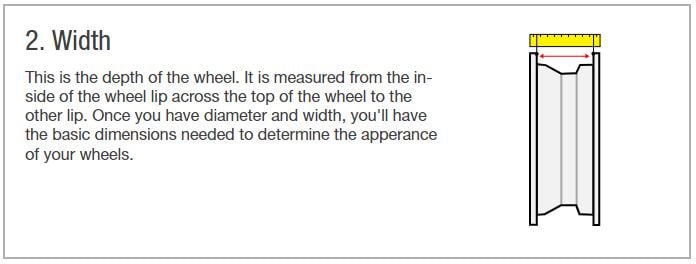

The wheel width is the measurement of how wide the wheel is where the tire is seated to it from inside to inside. To demonstrate how to measure rim width, take a tape measure and start at the inside of the wheel lip and bring it across to the inside of the wheel lip on the other side. Typical wheel widths are 6”, 7”, 8”, 9”, 10”, 12” as well as in-between (for example, 8.5") or wider measurements.

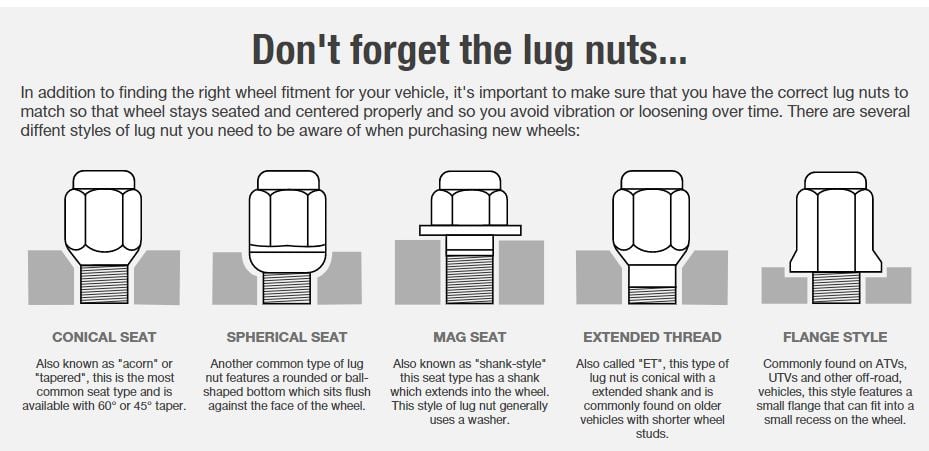

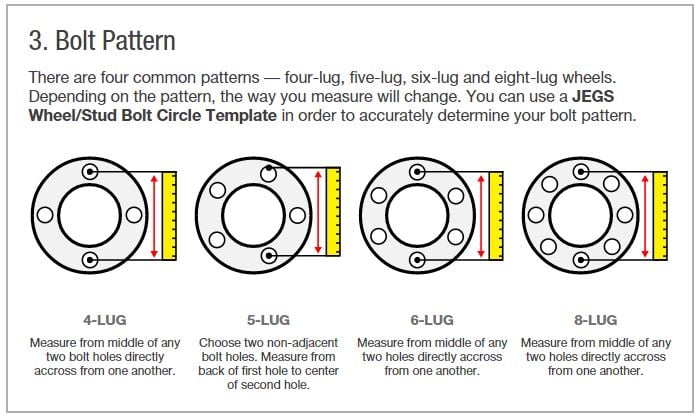

How To Measure Lug Spacing And How To Measure A 6-Lug Pattern

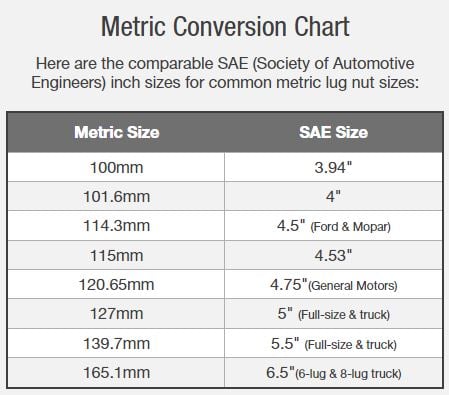

There are two different ways to measure lug spacing, depending on if the vehicle has an even (example, 4, 6, or 8 studs) or odd (example, 5 studs) number of lug nuts. The best way to understand lug spacing or the wheel bolt pattern is to visualize an imaginary circle that goes around and through all of the wheel lug nuts. The diameter, or measurement across that circle is your lug spacing. For an even number of lug nuts, the measurement is simple. Start with a measuring tape in the middle of one lug and go directly across the center of the wheel to the middle of the lug on the opposite side. This distance gives you the wheel bolt pattern or lug spacing. This is advertised as the number of wheel studs by the diameter. For example, 6 x 5.5”, meaning 6 studs and 5.5” is the diameter across the bolt circle. The measurement can be in millimeters or in inches, so if what you come up with in inches is not an even amount, it may be in millimeters or vice-versa.

If the number of lug nuts is odd (which typically would be 5), the measurement is slightly different. Since an odd number of lug nuts doesn’t allow you to measure perfectly across the center of the wheel, you need to start the measurement in the middle of one stud. Then go across the center of the wheel to the outer edge of the opposite stud (which will not be perfectly straight across). An example advertised measurement will be 5 x 4.75”. As with even lug nuts, the measurement may be in either inches or millimeters.

How To Measure Backspacing

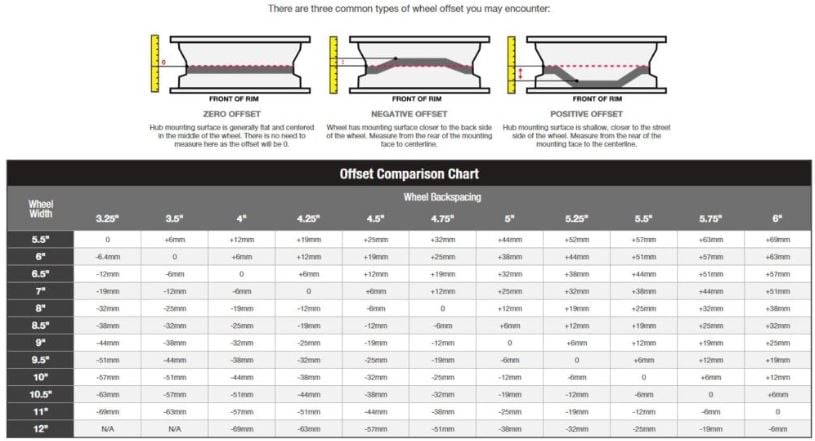

Wheel backspacing refers to the distance from the center of the backside of the wheel (where it mounts against the vehicle hub) out to where the wheel lip begins. The lower the backspacing is, the more “dish” the wheel will have and the further the wheel/tire will stick out of the wheel well. The higher the backspacing is, the less “dish” the wheel will have, and the more “tucked in” the wheel/tire will be in the wheel well. Another way to understand backspacing is to visualize how far in or out the “face” of the wheel is within the “barrel” of the wheel, which affects how far in or out of the wheel well the tire/wheel will be. It is very important to confirm the correct backspacing so that that wheel and tire will both fit and look correct on the vehicle.

How To Measure Wheel Offset

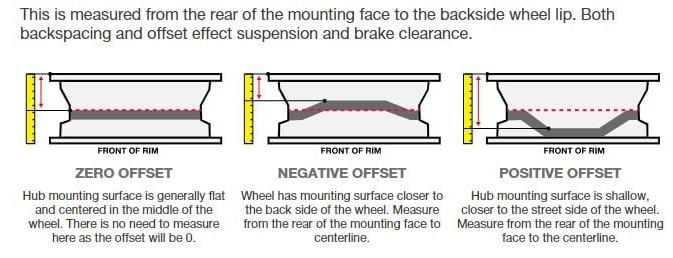

Wheel offset is another way of measuring how far in or out the wheel/tire will be in the vehicle’s wheel well. Offset is related to backspacing, but the way it is measured is different. The start of the measurement is the center of the back of the wheel, like backspacing. However, the end measurement is not to the beginning of the wheel lip. Instead, the end measurement is the exact center of the barrel of the wheel. To help understand, visualize looking directly over a wheel as though it was installed on the vehicle. If you were to slice that wheel perfectly in half, the line created completes the offset distance from the back of the center of the wheel. For example, +40mm is a common offset. This means that the distance from the direct center of the barrel of the wheel out to the inside of the backside of the face of the wheel is 40mm. It is positive with a “+” when the backside of the face of the wheel is further out than the exact center of the wheel barrel. When the offset is negative with a “- “, the back side of the face of the wheel is further in than the exact center of the wheel barrel. Typically, negative offset wheels are found on off road trucks as the wheels/tires stick out. Positive offset wheels are most often found on late-model vehicles. Essentially, positive offset is similar to high backspacing as negative offset is similar to low backspacing as it relates to the wheel/tire position in a vehicle’s wheel well.

Wheel Size Calculator

Wheel Offset / Backspacing Calculator

Enter the following values (leave the field blank for the measurement you want to find):

Wheel Width (in inches):

Backspacing (in inches):

Offset (in mm):

How To Measure For Custom Wheels

Having a strong understanding of how to measure wheel diameter, width, bolt pattern, backspacing, and offset will allow measuring wheels to be properly performed for custom wheels that will properly fit on your vehicle. One way to help you measure for custom wheels is to start with a wheel that fits properly in either the front or back and then compare specifications to the wheel you want to use. Keep in mind and allow for brake clearance, suspension compression, and steering in your measuring, which can reduce clearance and cause tire interference. Tire size also has to be factored in your measurements. You can speak to a JEGS technical associate for help in selecting the right wheel size if desired.