In the realm of automotive instrumentation, gauges are essential tools that provide crucial information about the performance and health of your vehicle. When it comes to gauges, there are two primary types: electric gauges and mechanical gauges. In this article, we will explore the key differences between these two types of gauges, highlighting their benefits, reliability, installation process, and pricing.

Benefits of Electric Gauges

Electric gauges, as the name suggests, rely on electrical signals to measure and display various parameters. Here are some advantages of electric gauges:

- Accuracy: Electric gauges are known for their high precision and accuracy. They provide real-time readings with minimal fluctuations, ensuring reliable and consistent information.

- Wide range of options: Electric gauges offer a broader range of options in terms of display styles, colors, and customizable features. This allows drivers to personalize their instrument clusters to their preferences.

- Ease of installation: Electric gauges are relatively easier to install compared to mechanical gauges. They require fewer physical connections and are compatible with modern electrical systems found in most vehicles. In addition routing wires is easier than routing the tubing found in pressure and temperature gauges.

Benefits of Mechanical Gauges

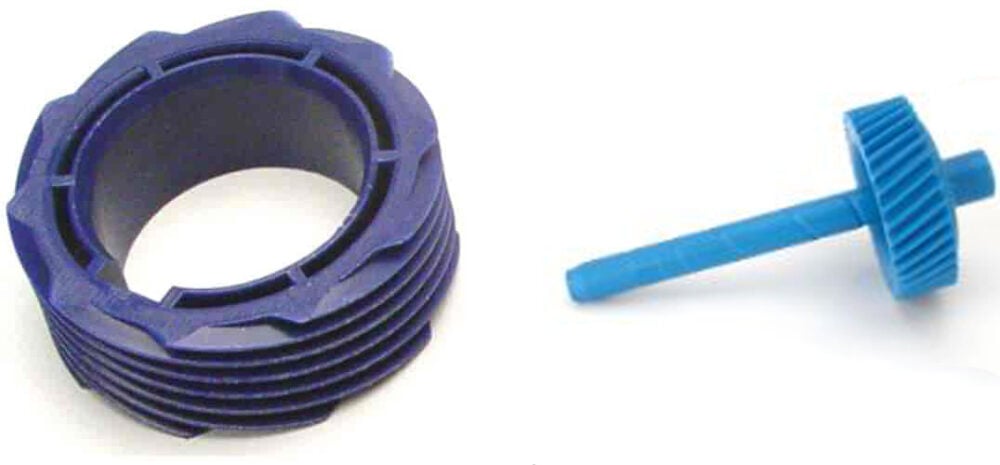

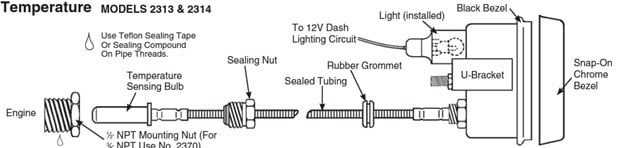

Mechanical gauges, on the other hand, operate using physical mechanisms and are widely used in older vehicles and certain performance applications. Here are some advantages of mechanical gauges:

- Reliability: Mechanical gauges have a long-standing reputation for their reliability. They are not affected by electrical system failures or wiring issues, ensuring accurate readings even in challenging conditions.

- Direct mechanical connection: Unlike electric gauges that rely on electrical signals, mechanical gauges have a direct physical connection to the measured parameter. This direct linkage enhances the response time and provides instant readings.

- Durability: Mechanical gauges are often built with robust materials such as stainless steel and brass, making them highly durable and resistant to vibration, heat, and other harsh environmental factors.

Reliability

When it comes to gauge reliability, both electric and mechanical gauges have their advantages and considerations. Electric gauges offer accuracy and precision but may be susceptible to electrical system malfunctions. Mechanical gauges, on the other hand, are renowned for their durability and resilience but can be affected by mechanical wear over time and are a little more difficult to install. Choosing the most reliable gauge depends on the specific application and personal preferences.

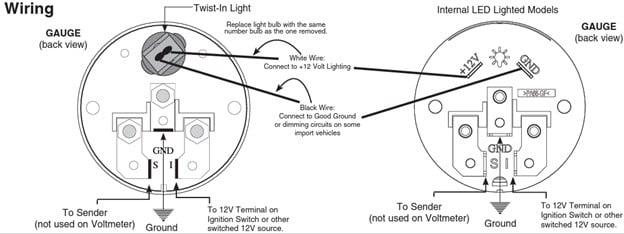

Installation

The installation process for electric and mechanical gauges differs significantly. Electric gauges require connecting the gauge to the electrical system, typically using sensors or sending units. This involves routing wires and ensuring proper grounding. In contrast, mechanical gauges require running physical tubing or cables from the gauge to the engine or system being measured. This can be more labor-intensive and may require additional modifications, especially in vehicles not originally equipped with mechanical gauges.

Pricing

In terms of pricing, electric gauges tend to be more expensive than their mechanical counterparts. The additional cost is due to the complex electronics involved in electric gauge systems. Mechanical gauges, on the other hand, have simpler construction and do not rely on electronic components, making them more affordable options for those on a budget.

Understanding the differences between electric and mechanical gauges is crucial when choosing the right instrumentation for your vehicle. Electric gauges offer accuracy, customization, and ease of installation, while mechanical gauges excel in reliability and durability. By considering factors such as the specific application, vehicle type, and personal preferences, you can make an informed decision about which type of gauge is best suited to meet your needs. Ultimately, both electric and mechanical gauges serve the purpose of providing vital information about your vehicle's performance, allowing you to monitor and optimize its operation.