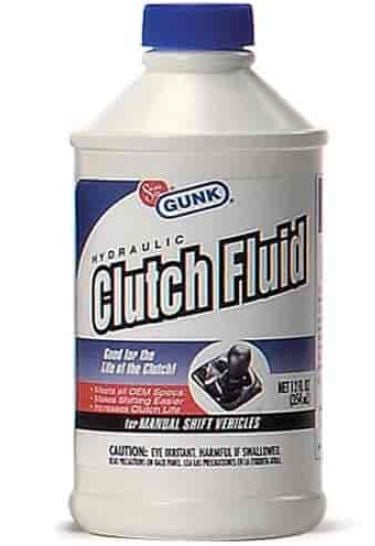

Most car owners know the importance of regular vehicle service. Routinely changing your motor oil, replacing the engine air filter, rotating the tires, these are basic maintenance items. But if you drive a manual transmission vehicle from the 80s or 90s onwards, there may be another item to consider: hydraulic clutch fluid.

To avoid any confusion, though, note that "clutch fluid" doesn't actually exist as a separate substance; it's simply brake fluid used in a different system (though some manufacturers will label the fluid as "clutch fluid"). So when we mention "clutch fluid," we're referring to the brake fluid used in the hydraulic system to enable the smooth transfer of force from your foot on the clutch pedal to the clutch slave cylinder or hydraulic release/throw-out bearing.

In general, you should change your brake/clutch fluid every two years to keep it free of dirt and other contaminants that may affect performance. As for levels, while a gradual loss of clutch fluid is expected over time, it usually only requires occasional topping off. If there is a sudden drop in the fluid level in the master cylinder, this almost always indicates a leak.

Well, good news, JEGS is here with step-by-step instructions for checking and changing your hydraulic clutch fluid. We’ll cover the various clutch types, clutch fluid vs brake fluid, and further review how often you should change your clutch fluid.

Hydraulic Clutch Types

So, why should you know about the different clutch types? Because it may affect the type of hydraulic fluid you need or whether your vehicle uses clutch fluid.

Using the wrong fluid, being low on fluid, or having contaminated fluid, increases the chances of the system not receiving enough hydraulic pressure, reducing clutch performance and potentially causing lasting damage.

Conventional Hydraulic Clutch System

A conventional hydraulic clutch is the standard system found in many manual transmission vehicles, especially those from the 80s and 90s. The different parts of a hydraulic clutch include a master cylinder, slave cylinder, throw-out/release bearing, and fork, depending on the system.

As for how the system works, when you press the clutch pedal, the master cylinder transforms the force from your foot into hydraulic pressure. This pressure travels through the hydraulic line to the slave cylinder, which uses this pressure to exert force on a part called the throw-out or release bearing.

In some systems, there is also a fork mechanism involved, which helps move this force from the slave cylinder to the release bearing.

Once this force reaches the throw-out bearing, it acts on the pressure plate. This pressure pushes the pressure plate away from the clutch disc, disconnecting it from the engine's flywheel. When this happens, the transmission and engine are decoupled, allowing you to change gears or allow the engine to idle while the transmission is in gear.

Once you release the clutch pedal, the hydraulic pressure decreases, causing the throw-out bearing to retract. The springs in the pressure plate pull it back towards the clutch disc, which re-engages with the flywheel, reconnecting the engine and the transmission and allowing the vehicle to move.

Hydraulic Clutch with Concentric Slave Cylinder

Hydraulic clutches with concentric slave cylinders are a more modern design in some newer vehicles. Here, the slave cylinder and release bearing are combined into one unit around the gearbox input shaft.

This design ensures a more direct application of hydraulic pressure to disengage the clutch, reducing the risk of incomplete disengagement, which can result in grinding gears or poor gear shift quality.

However, the close proximity of all the components makes this system more susceptible to contamination from tiny metal shavings or dust.

Hydraulic Clutch with Dual Clutch Transmission

Dual clutch transmission systems have two clutches, as seen in performance cars like the VW Golf GTI or Audi S3. One clutch handles the even gears while the other manages the odds—allowing for quick, seamless gear shifts.

Electro-hydraulic clutches, where an electric pump maintains hydraulic pressure instead of the clutch pedal, may also be used in these systems.

Given their demanding nature, often operating in extreme temperatures and at high rpm, these systems require high-quality fluids formulated to resist viscosity breakdown even at high temperatures.

If you're unsure about the type of clutch fluid your vehicle takes, refer to its owner’s manual for manufacturer recommendations.

Steps to Checking Hydraulic Clutch Fluid (& Changing if Needed)

Checking your clutch fluid is simple and takes just a moment. It's worth noting though, clutch fluid, like brake fluid, can damage vehicle paint, so be careful to avoid spills.

Below we’ve outlined the basic steps:

- Gather Your Tools & Safety Equipment: To check your hydraulic clutch fluid, you really don’t need any special equipment, other than maybe a clean rag and a flashlight.

As a safety measure, ensure your vehicle is parked on a level surface, the engine is off, and the car has had time to cool.

- Find the Clutch Reservoir: The clutch fluid reservoir is usually located under the hood, near the back of the engine compartment, often near the brake fluid reservoir on the firewall. Generally, you’ll be looking for a black or yellow cap, likely with the vehicle’s recommended fluid type (DOT-3, DOT-4, etc.).

Consult your vehicle's manual if you have difficulty locating it. The reservoir is usually transparent or semi-transparent, enabling a visual check of fluid levels.

- Check the Clutch Fluid Level: Ensure that the fluid level is between the minimum and maximum markings on the side of the reservoir.

If the fluid is below minimum, it may indicate a leak in the system and should be topped off with the appropriate fluid as indicated by your vehicle's manual, followed by an inspection of the system for the source of the leak.

- Inspect the Clutch Fluid Color & Clarity: Clutch fluid should be relatively clear, with a slightly yellowish color.

If the fluid looks dark, cloudy, or has visible particles floating in it, this could indicate contamination, meaning it’s time for a fluid change.

- Test the Clutch: After checking the fluid, test the clutch by starting your vehicle and pressing the clutch pedal. The pedal should feel firm and return smoothly when released as well as allow smooth engagement and disengagement with transmission gears.

If it feels spongy or sticks to the floor, it may indicate a problem with the hydraulic system, such as air in the line or a failing master or slave cylinder, requiring inspection and testing of each component to determine a repair solution.

Changing Your Clutch Fluid

As you can see from the above steps, checking your clutch fluid is pretty easy, but changing it, as well as the (air) bleeding process, is a bit more complicated. For some car owners, having a professional mechanic perform the service may be the best bet, but if you’re a savvy DIYer you should be fine following a shop manual for your specific application.

The process involves removing the old, potentially contaminated or degraded fluid from the hydraulic clutch system and replacing it with fresh fluid. If done incorrectly, you risk introducing air into the system, which can cause issues with the clutch system.

These are the basic steps:

- Begin by removing the old fluid from the master cylinder using a suction tool. Take care not to drip fluid and protect surrounding parts to avoid paint damage. After the old fluid has been removed, top it off with fresh fluid.

- Locate the bleed valve on the slave cylinder. In most cases, the vehicle will need to be safely lifted to access the slave cylinder more easily.

- Attach a tight-fitting tube or hose to the bleeder valve and place the other end in a container to catch the old fluid.

- Have a helper in the vehicle who will first push down on the pedal. As they do this, open the valve with a wrench and press the clutch pedal to force the old fluid out.

- Once the old fluid stops draining, close the bleeder valve while keeping the foot on the clutch pedal. The helper in the car can then release the clutch pedal to prevent air from being drawn into the system through the open bleeder.

- Refill the clutch fluid reservoir with new fluid.

- Repeat the bleeding process until only clean fluid comes out (and no air or bubbles).

- Lower the vehicle back down to the floor.

- Ensure the fluid reservoir is filled to the correct level, and then close it.

If you’re not confident performing the service yourself, consult your vehicle's owner’s manual or a professional mechanic.

What's the Difference Between Clutch Fluid & Brake Fluid?

As we mentioned earlier, there's no inherent difference between clutch fluid vs brake fluid—they are, in fact, the same thing. The term "clutch fluid" is just a way to refer to brake fluid when it is used in a hydraulic clutch system.

Most often, DOT-3 or DOT-4 fluids are used for both systems. These are hydraulic fluids designed to withstand the high pressures and temperatures associated with braking and clutch operation.

So, whether you're topping off your brake fluid or "clutch fluid," know that you're actually dealing with the same substance. Just make sure to confirm which DOT rating your vehicle’s clutch needs, as it may differ from the brake fluid.

How Often Should You Change Clutch Fluid?

How often you need to change your clutch fluid really depends on the type of vehicle, driving conditions, and type of hydraulic clutch system used. However, a general rule of thumb is to change your clutch fluid every two years or every 24,000 miles or so. This is roughly the same interval as brake fluid, given they're the same substance.

You should also perform regular visual inspections of the clutch fluid's clarity. If the fluid appears dark, cloudy, or has visible particles floating in it, this could indicate contamination, suggesting it's time for a fluid change.

This frequency may need to be increased if your vehicle is often subjected to more strenuous conditions, like heavy towing, off-road driving, or high-performance driving. These conditions can cause your clutch fluid to degrade quicker, requiring more frequent changes.

Moreover, clutch systems with concentric slave cylinders or dual-clutch transmissions often require more regular fluid changes due to their complexity and high-performance nature.

Consider JEGS For All Your Hydraulic Fluid Needs

Knowing how to properly maintain a hydraulic clutch system is a great skill to have if you own a car with a manual transmission.

In general, you should be fine by routinely check your clutch fluid level and keeping an eye out for any changes, as significant reductions could indicate a leak.

When it comes to regular maintenance, quality parts, or expert advice, trust JEGS. We're here to ensure your ride operates smoothly, reliably, and efficiently. Have more questions? Contact our team today.