There are important things to understand when learning how to flare stainless steel brake lines as well as tubing for AN fittings. Using a flaring tool properly as well as preparing the tube correctly will prevent potential leaks and headaches. Below are answers to common questions about flaring stainless steel tubing, steel tubing, and flaring with a 37 or 45-degree tool.

Types of Stainless Steel Tubing

When working with stainless steel tubing, it's essential to consider the different types available. Common options include 304 stainless steel, known for its general corrosion resistance, and 316 stainless steel, which offers superior resistance to corrosion and chemicals. Understanding the characteristics and applications of each type can help you choose the most suitable stainless steel tubing for your specific needs. Consider factors such as the environment, temperature, and intended use to ensure optimal performance and longevity of your tubing.

Importance of Using Quality Tubing and Fittings

Using high-quality stainless steel tubing and fittings is paramount to ensure leak-free connections and reliable performance. Inferior materials may compromise the integrity of your flares, leading to potential leaks and system failures. Invest in reputable brands and ensure the tubing and fittings meet industry standards and specifications. Prioritize quality to ensure the durability and safety of your brake lines or other applications.

Types of Flares for Brake Lines

When it comes to flaring lines, there are two common types of flares: single flare and double flare. Single flares are typically used for low-pressure applications like carbureted fuel systems, while double flares are suitable for high-pressure systems like brake systems. Understanding which type of flare to create is crucial for a safe and reliable brake system.

Size Guide for Stainless Steel Brake Lines

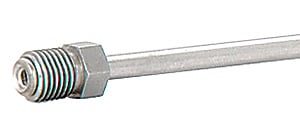

Selecting the right size for your stainless steel brake lines is essential for proper fit and function. Always refer to your vehicle's specifications or consult a professional to determine the appropriate size. Using the correct size ensures a secure and leak-free connection. Too large or too small of diameter can cause braking performance problems or even failure.

Tips for Selecting the Right Flaring Tool

Selecting the appropriate flaring tool is crucial for achieving accurate and reliable flares. Consider factors such as the type of flare required (single or double), the tubing size, and the material being used. Additionally, evaluate the style of the flaring tool, such as bench-mounted or handheld, based on your specific needs and available workspace. Choosing the right flaring tool ensures precise results and simplifies the flaring process.

How to Flare Tubing / How to Flare Stainless Steel Brake Lines

When flaring stainless brake line (for example), first make sure the end of the pipe you are flaring is cut square with a tubing cutter to prevent the chances of a leak. After the end is cut evenly, ensure there are not any burrs with a de-burring tool.

Then chamfer the edge of the pipe per the tool instructions (example, approximately 0.25 x 45 degrees”). Next, de-burr the bore of the pipe. Also, if the pipe is plastic covered, remove at least 3mm of the plastic covering from the end to be flared.

You will then need to choose the correct punch and die for the size tube and type of flare you will be creating, typically included with the flare tool set.

Whether using a 45-degree or 37-degree flaring tool stainless steel, aluminum, or steel tubing, the steps are similar in the flaring process. Be sure to slide the tubing nut on before you flare the end of the pipe to avoid having to re-flare the end.

When Flaring The Tube For A 37° Single Flare...

You must use a flaring tool that does a 37° Single Flare. It's important to use lube on the flaring tool and the tube. To create a 37° Single Flare, first clamp the tube flush in the correct size fixture. When you make the tube flush, this will set the depth of the flare. Next, the forming die must be centered on the tube or the flare will be off center. By using the "V" shaped die this will create the 37° Single Flare that you need for AN fittings. The tubing must be flush with the tool, once that's done, by using the 37° die you turn the tool to create your flare.

When flaring the tube for a 45° Double Flare...

You must use a flaring tool that does a 45° Double Flare. It's important to use lube on the flaring tool and the tube. To create a 45° Double Flare, first clamp the tube in the correct size fixture. Set the depth by aligning the tube with the Bubble Flare die. The edge of the tube must be even with the edge of the Bubble Flare die. Place the tube in the correct size hole on the bar and set the depth of the flare by aligning the edge of the tube and the bubble flare die. Next, the forming die must be centered on the tube or the flare will be off center. Insert the bubble flare die into place on the tube (The tail of the bubble flare die will be inserted inside the tube). By using the "V" shaped die & aligning it with the bubble flare die and the tube, you will start by turning in the "V" shaped die. The "V" shaped die will start pressing on the bubble flare die and creating a bubble flare. Once the bubble flare is complete, the double flare is completed by removing the die & forming the tube with the "V" shaped die. This will create an inverted flare which will complete the flare. Next, use the 45° "V" die to create an inverted flare and complete the double flare.

Brake Line Flaring Tool

When it comes to flaring brake lines, using a dedicated brake line flaring tool is essential for achieving professional results. These tools are designed specifically for brake lines and ensure consistent and precise flares.

Tips for Flaring Without a Tool

In some situations, you may need to flare tubing without access to a dedicated flaring tool. While it's recommended to use a proper tool for the best results, you can create basic flares using alternative methods in a pinch. However, keep in mind that these flares may not be as reliable as those created with a specialized tool and are therefore not recommended.

What is a Decent Double Flare Tool?

There are different styles of steel and stainless steel flaring tool options, including tools to double flare stainless steel brake line. Some versions are designed to be mounted in a bench vise while others are hand-held. JEGS offers a large selection of double flare tools to help with flaring stainless steel tubing as well as non-stainless tubing. These options are made from high-quality components and assembly. They are also simple to use when flaring stainless steel brake lines, fuel lines, transmission lines, or any other lines requiring a double flare.

Common Mistakes to Avoid

When flaring stainless steel tubing, it's important to avoid common mistakes that may compromise the quality of your flares. Ensure the tubing is cut square using a tubing cutter and remove any burrs using a deburring tool. Properly chamfer the edge of the pipe according to the tool instructions to prevent leaks. Additionally, if the tubing is plastic covered, remove an adequate amount of the plastic covering from the end to be flared. By avoiding these mistakes, you can achieve tight and reliable flares.

Safety Precautions

Working with flaring tools and stainless steel tubing requires adherence to safety precautions. Always wear appropriate personal protective equipment, such as safety glasses and gloves, to protect against sharp edges or debris. Ensure proper ventilation if lubricants or chemicals are used. Work in a well-lit area to maintain clear visibility. By prioritizing safety, you can prevent accidents and injuries during the flaring process.

Maintenance and Storage of Flaring Tools

To prolong the lifespan and maintain optimal performance of your flaring tools, regular maintenance and proper storage are crucial. Clean the tools after each use, lubricate moving parts, and inspect for any wear or damage. Store the tools in a dry and secure place to prevent rust or other forms of deterioration. By practicing proper maintenance and storage, your flaring tools will remain in excellent condition and consistently deliver precise flares.

Learning how to flare stainless steel brake lines and tubing is a crucial skill for achieving secure and leak-free connections. By understanding the different types of stainless steel tubing, the importance of using quality materials, and selecting the right flaring tools, you can ensure successful flares. Additionally, avoiding common mistakes, prioritizing safety, and maintaining and storing your flaring tools properly will contribute to consistent and reliable results. By utilizing the recommended resources, you can further enhance your knowledge and proficiency in flaring stainless steel brake lines and tubing.

Can't Find the Lines, Fittings, and Flare Tools You Are Looking For?

A JEGS expert is ready to answer your questions and help you find the flare tools, lines, and fittings that you require for your specific application as well as help with how to flare tubing.