During engine tuning and maintenance, one overlooked thing is not setting the proper idle mixture for a car with a carburetor. It’s not talked about because these engines are less common than they used to be, and, two, it’s not the most fun or exciting repair to make. Plus, it’s unlikely to help you go any faster in a straight line, which is what most horsepower junkies are after.

That said, if you care about your engine, you need to care about the idle mixture of your carburetor because your engine will likely be idle a lot. Failing to set the right timing can impact your engine’s performance, damage the carburetor, and lead to several other problems.

Read on to learn everything you need to know about carburetor adjustment.

Understanding Optimized Engine Idle Mixture and Speed

It’s essential to understand optimized engine idle because it’s the air-to-fuel ratio that your car will spend a lot of time at. If this mixture is off, you can waste fuel, end up with misfires, spark plug fouling, and deal with a rough idle. Failing to tune your carburetor to the proper specifications can cause these issues to get worse and damage your engine progressively.

When it comes to what an idle mixture is, the concept is pretty simple. It refers to the air-to-fuel ratio entering your engine’s cylinders. If you have the wrong balance here, your engine can misfire and perform poorly – to put it lightly.

Now, if you want to keep your engine healthy, you’ll want to optimize this mixture by tuning your carburetor to dump the necessary amount of fuel and air in the cylinders for combustion. The owner's manual should contain information about the appropriate ratio for your vehicle.

Why You Need to Set Your Timing Before You Start Tuning Your Carburetor

Setting your timing before you start tuning your carburetor is essential for several reasons, primarily because it’s the baseline for your engine’s performance. When you set the timing before tuning your carburetor, you know the baseline air-to-fuel ratio to take it from there.

Having the wrong timing at idle might translate to having the wrong timing as you begin accelerating. Additionally, the wrong ignition timing can result in other problems that lead to misdiagnosis of other issues. For example, the wrong timing can give you a rough idle, ping, or pre-detonation, which might make you think that your carburetor is acting up when it’s fine.

It’s also important to note that the wrong timing will give you nightmares regarding emissions. With the wrong timing, your engine will produce more harmful emissions, and you might even fail your next inspection because of this if yours is a street car.

The Correct Procedure for Setting Optimized Timing and Speed

Considering everything, the correct procedure for optimized timing can be done in a few steps that will vary based on the type of carburetor you have and your specific tuning requirements. Still, you can follow the steps below to get the basics down.

First, warm up the engine while it’s idling. Then, check and set the idle speed. To set the idle speed, locate the idle speed and adjustment screws found on the carburetor, typically around the cable linkage connection. From there, adjust the screw or screws until you have the manufacturer’s recommended RPMs, which can be found online or in your vehicle’s manual (typically somewhere between 800-1,000 rpms). We recommend getting your carburetor to this point before you start tuning.

Once you have the idle speed and adjustment screws tightened, it’s time to move on to the mixture adjustment screw. This screw is found on the side or front of the carburetor, and you should start by turning clockwise until the engine begins running poorly. Make a note of this position and try to avoid keeping it here. Once you know this position, turn the screw counterclockwise until it runs poorly. Essentially, you want to see how far in and out you can move the screw until the engine starts having problems. If you know where it runs poorly, you can set the adjustment to the middle for the best results and tune your carburetor from there. If you have a vacuum gauge available, most carburetor idle adjustment is done with the goal of having the most engine vacuum with the screw at "lean" setting; meaning turned in the farthest before the vacuum goes down as well as engine idling performance.

The last step is to return to the idle speed and check it out. Unfortunately, tinkering with the adjustment screw for the fuel mixture can result in problems with the idle speed. Reset that screw back to the proper position, and you’re all set.

To ensure everything works properly, test drive the car and check how it runs at different RPMS.

How Much Vacuum Should My Engine Be Making?

When the engine runs at high speeds or idle, it creates a vacuum within the intake manifold. This is an area with low pressure that pulls air into the carburetor. Without the right vacuum, the engine won’t pull in the necessary air for you to have the correct air-to-fuel ratio.

The amount of vacuum your engine needs to make varies based on your engine type, camshaft specifications, and even your vehicle’s elevation. Typically, a combustion engine will produce a vacuum of 14 to 21 inches of mercury (in. Hg) at sea level. If you have a low reading, like 5 to 10 in. Hg, there is a good chance you have a leak in your intake manifold, which could be a gasket leak. Note that most power brake systems require at least 18 inches of vacuum, so if your vehicle is used primarily on the street, you want to confirm if you have enough vacuum for properly operating power-assist brakes.

Vacuum level may also be reduced if your engine has wear and tear. Damaged engines have a lower vacuum due to internal leaks, and the vacuum levels can change if you have a forced induction system.

Measuring your vehicle’s vacuum is vital because the carburetor operates by engine vacuum. It regulates the amount of air let through the carburetor by opening and shutting the butterfly valve. The carburetor has to react to throttle input and vacuum to supply the proper air-to-fuel ratio at idle and other speeds.

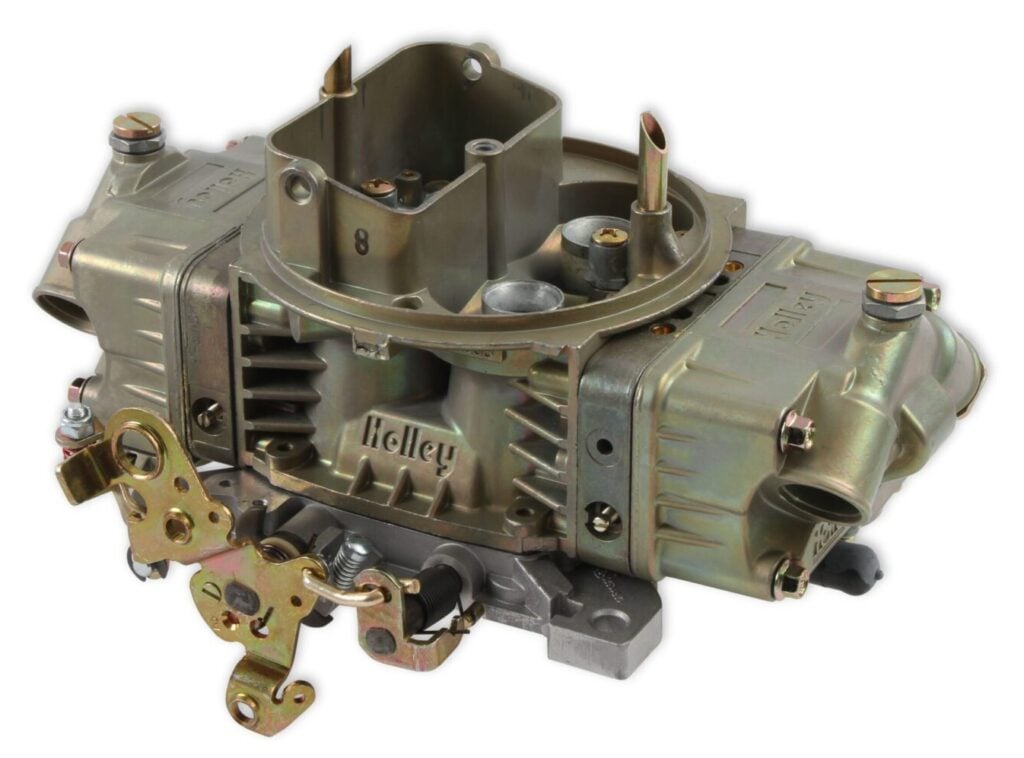

Need a new carburetor, repair seals, or tools to get the job done? Find everything you need for your carbureted engine at JEGS.