When modifying your vehicle with an LS engine swap, one important decision you'll need to make is whether to use a return style fuel system or a returnless. This choice greatly impacts the fuel efficiency, performance, and overall functionality of your engine.

If you’re not sure what a returnless or return style fuel system is, no worries; this guide caters to both novice enthusiasts and experienced gearheads alike.

We’ll dive into the details of both fuel system types, helping you understand their workings, benefits, and drawbacks. Further, we'll also explore aftermarket fuel pressure regulators, "Corvette-style" fuel filter/regulator units, and other regulation methods.

By the end of this guide, you'll understand and be able to identify which fuel system aligns best with your LS engine swap goals.

Let’s get started.

Return Style Fuel System LS Engines

In a return style fuel system, an inline LS swap fuel pump sends fuel from the tank to the engine via a feed line. Any excess fuel not used by the engine is then sent back to the tank through a separate “return” line.

To ensure that the fuel delivered to the engine is clean and free of harmful contaminants, a 10-micron (or better) inline fuel filter is typically positioned on the feed line in a return style fuel system.

Pros and Cons of a Return Style Fuel System in LS Engine Swaps

Pros of a Return Style Fuel System

- Stable Fuel Pressure: Due to the fuel constantly recirculating, this system is able to maintain consistent fuel pressure, meaning the engine always has enough to perform optimally.

- Reduced Fuel Temperature: The continuous movement of fuel helps keep the fuel cooler, which can enhance engine efficiency. This system also reduces the risk of vapor lock, which is when backpressure restricts flow, which can cause the fuel to boil in the lines

- Customization and Tunability: Return style systems are often preferred for modded engines, as they can better accommodate changes in fuel demand. This makes return style setups ideal for tuning and performance enhancements.

Cons of a Return Style Fuel System

- Complexity and Cost: The return style system is more complex than returnless systems, potentially leading to higher installation and maintenance costs.

- Space Constraints: The additional lines and components may require more space, which can be challenging in certain engine configurations.

- Fuel Aeration Risk: Returning fuel to the tank can introduce air bubbles, causing aeration that may impact engine performance, especially in performance-tuned vehicles.

How to Identify a Return Style Fuel System

- Dual Fuel Lines: The easiest way to identify a return style system is via two distinct fuel lines. The feed line that carries fuel from the tank to the engine, and the return line that sends unused fuel back to the tank.

- Integrated Fuel Pressure Regulator: You can also identify a return style setup by spotting the integrated fuel pressure regulator on the LS engine’s fuel rail.

Returnless Style Fuel System LS Engine

In returnless fuel systems, an in-tank LS swap fuel pump (like this JEGS unit) sends fuel from the tank to the engine via a feed line, but uniquely, there is no return line. This streamlined design ensures that only the fuel needed by the engine is delivered.

These systems typically forgo a built-in pressure regulator in favor of alternative methods like using an external fuel pressure regulator. This approach allows for more precise fuel management, particularly in performance-tuned setups.

In return setups, the main fuel filter is usually positioned on the feed line, filtering the fuel before it reaches the engine. In returnless systems, the fuel filter is typically located near the tank.

Pros and Cons of a Returnless Style Fuel System in LS Engine Swaps

Pros of a Returnless Fuel System

- Simplicity and Lower Cost: The returnless system is simpler and often less expensive than return style systems. It requires fewer components and lines, which can also simplify installation.

- Reduced Heat Transfer: With no fuel returning to the tank, the chance of heat transfer from the engine to the fuel tank is minimized, potentially improving overall fuel efficiency.

- Lower Risk of Fuel Aeration: Without a return line, the risk of introducing air into the fuel system is greatly reduced, leading to more consistent fuel delivery and engine performance.

Cons of a Returnless Fuel System

- Less Precise Fuel Pressure Control: The returnless system might not offer the same level of precise fuel pressure control as a return style system, which can be a drawback for highly tuned or performance-focused engine setups.

- Potential for Fuel Starvation: Under high performance or high fuel demand situations, there's a higher risk of fuel starvation, as the system doesn’t recirculate excess fuel back to the engine.

How to Identify a Returnless Style Fuel System

- Single Fuel Line: The most obvious sign of a returnless system is seeing only one fuel line – the feed line. Unlike the return style, there’s no line returning excess fuel to the tank.

- Fuel Pressure Regulator Location: As mentioned, in returnless systems, the fuel pressure regulator is often located at the fuel pump or in the tank, rather than on the fuel rail.

- Fuel Rail Design: The fuel rail in a returnless system usually lacks the extra fittings or ports for a return line, which are visible in return style systems.

Aftermarket Fuel Pressure Regulators

Aftermarket fuel pressure regulators are great for fine-tuning the fuel system in LS engine swaps, allowing for precise fuel pressure adjustments to support high-flow fuel pumps.

These regulators are especially beneficial for advanced tuning and are often boost-referenced, meaning they can increase fuel pressure in tandem with the engine's boost, enhancing the tuning capability of the LS engine.

When using aftermarket regulators, it's important to pair them with a high-quality inline fuel filter to ensure the fuel system is free from contaminants. JEGS offers a range of top-notch aftermarket fuel filters and pressure regulators from reputable manufacturers like Aeromotive, Holley, Magnafuel, Quick Fuel, and Fuelab.

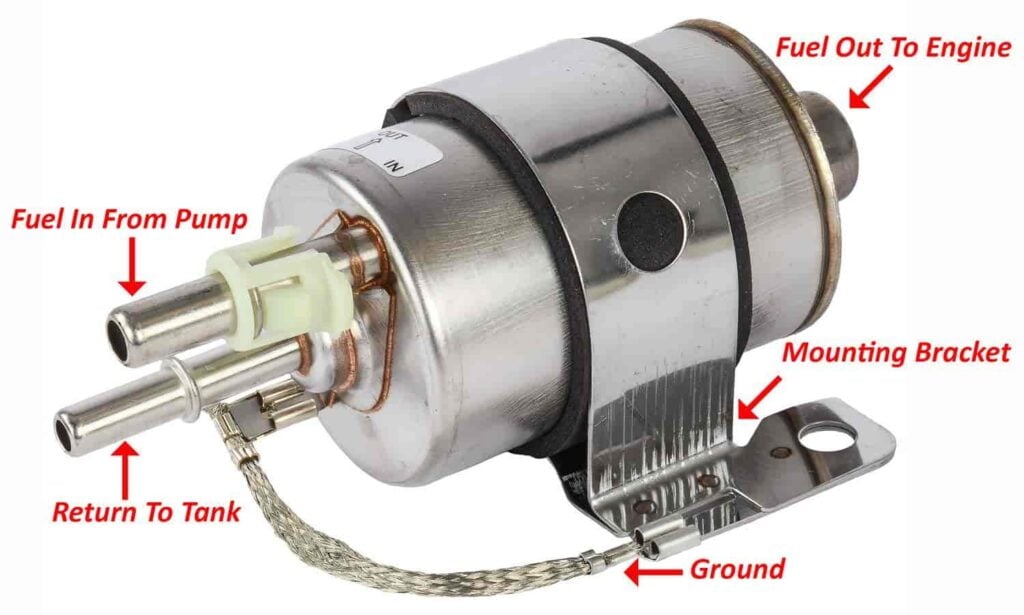

Corvette Style Filter and Regulator Unit

A "Corvette" style filter and regulator unit is essentially a streamlined solution for LS engine swaps, combining fuel filtration and pressure regulation in one efficient package. Ideal for LS swaps in street rods, street/strip cars, trucks, and custom builds, this unit simplifies the fuel system setup.

JEGS offers the LS Bypass fuel filter, a product tailored for these applications. It features an internal regulator and return line, ensuring easy installation.

When used with compatible fittings, this type of setup further eases the plumbing process of the fuel system. This integrated unit is a practical choice for maintaining fuel cleanliness and optimal pressure in LS engines.

Other Fuel Pressure Regulation Methods

For LS engine swaps, two less common fuel pressure regulation methods are internally regulated fuel pump modules and pulse width modulation (PWM).

Internally Regulated Modules

Internally regulated modules are available as OEM and aftermarket options. These simplify installation by requiring only a single fuel line to the engine, making them truly "return-less."

Note that these units are usually system-specific, and selecting the correct one may require expert guidance due to serviceability concerns, such as needing to drop the fuel tank to access the internal regulator.

PWM or Pulse Width Regulation

PWM, while prevalent in modern OEM setups, aren’t as common in the aftermarket. This method involves the engine's ECU controlling fuel pressure.

The ECU regulates the fuel pump by sending signals to adjust its volume and pressure output, thereby meeting the engine's fuel requirements. Implementing PWM in an engine swap can be more complex but offers precise control over the fuel delivery system.

JEGS: For All Your Automotive Needs

Congratulations, you’re now an expert on LS engine fuel systems. With your newfound knowledge you can confidently identify which fuel system works best for you and your custom LS swapped project.

For all your fuel system needs, consider JEGS, a leading supplier of performance auto parts. Complete your order online and have your products sent straight to your garage. Still have questions? Contact our team today.