Building a fuel system requires careful planning and the right system components. The fuel regulator is an important part as it is responsible for providing the correct fuel pressure to either the carburetor or fuel injection system. It is important to understand the difference between a return-style and a returnless-style fuel system for both carbureted and fuel injected systems when planning and building your fuel system. To help you with your research, we have provided the below answers to common questions about return and returnless fuel systems and regulators:

Maintaining the correct fuel pressure is of utmost importance for achieving optimal engine performance, fuel efficiency, and emissions control. Fuel pressure plays a crucial role in ensuring proper fuel atomization, which refers to the process of breaking down fuel into small, uniformly distributed droplets. Efficient fuel atomization allows for thorough mixing of fuel with air, promoting complete combustion and maximizing power output. Additionally, precise fuel pressure control ensures that the fuel-air mixture remains within the ideal stoichiometric ratio for efficient combustion, minimizing fuel wastage and reducing harmful emissions. By regulating fuel pressure, the fuel pressure regulator enables consistent fuel delivery, ensuring smooth engine operation, improved fuel economy, and reduced environmental impact.

How A Fuel Pressure Regulator Works

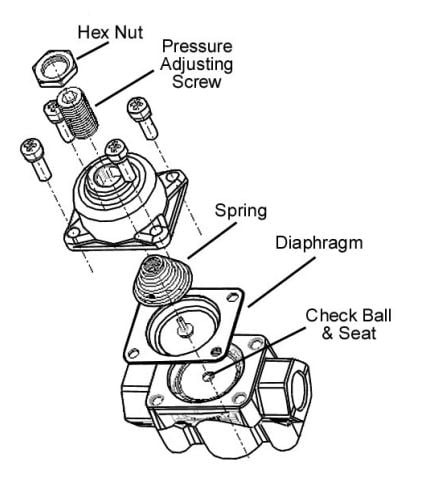

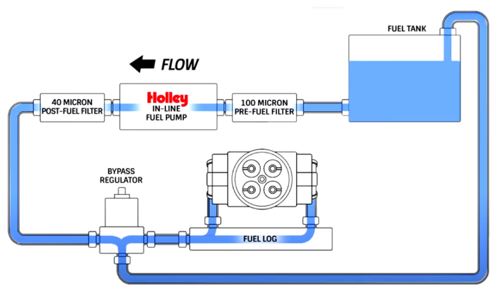

A fuel pressure regulator with bypass (also called "return-style") is a component that controls fuel system pressure using a spring and diaphragm that is either adjustable or preset. A Fuel pressure regulator is typically installed between the fuel pump and carburetor or throttle body, but can also be at the end of a fuel injection rail. Fuel from the fuel pump flows into the inlet and exits the outlet of the regulator to the carburetor or fuel injection system. Built into the diaphragm is a plug that rests in the bypass port below the set fuel pressure. When the set pressure is exceeded, the fuel pressure pushes against the diaphragm and spring, which lifts the plug out of the internal bypass port. This allows excess fuel into the bypass port to be routed / returned back to the gas tank. Some bypass style fuel pressure regulator designs include a boost or vacuum reference, which provides additional pressure as vacuum drops or boost increases, to prevent fuel starvation under heavier acceleration.

Fuel Pressure Range

The optimal fuel pressure range can vary depending on the type of engine and its specific requirements. In carbureted engines, typical fuel pressures often range between 4 to 7 psi (pounds per square inch). For naturally aspirated fuel-injected engines, the fuel pressure range usually falls within 30 to 50 psi. In the case of turbocharged engines, higher fuel pressures are typically required to meet the increased fuel demands under boost, ranging from 40 to 70 psi or even higher. Regardless of the engine type, the fuel pressure regulator plays a vital role in maintaining the fuel pressure within the appropriate range. It ensures that the fuel pressure remains consistent and prevents it from exceeding or falling below the recommended levels, thus guaranteeing optimal engine performance, fuel efficiency, and longevity.

The Fuel Return Line

In return-style fuel systems, the fuel return line plays a crucial role in maintaining proper fuel pressure and preventing fuel system overpressure. As fuel is pumped from the tank to the engine, not all of it is consumed by the engine's combustion process. The excess fuel, which is not utilized by the engine, is redirected back to the fuel tank through the fuel return line. This serves two important purposes. Firstly, it ensures a continuous flow of fuel within the system, allowing for consistent fuel delivery to the engine. Secondly, it prevents fuel system overpressure by relieving the excess pressure that could build up if the fuel was not returned. By regulating the fuel pressure and facilitating the return of unused fuel, the fuel return line helps maintain the proper functioning of the fuel system, promoting efficient fuel utilization, and preventing potential damage or safety issues associated with excessive fuel pressure.

What Is Not A Characteristic Of A Returnless Fuel System?

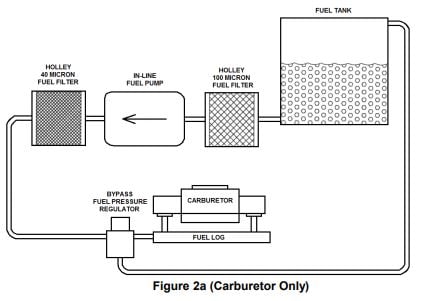

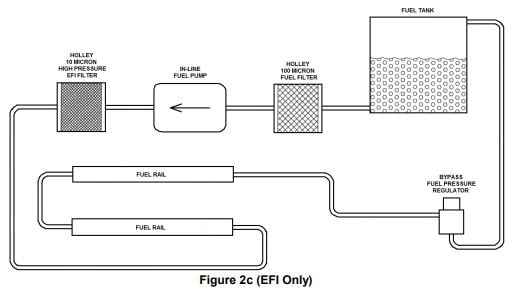

In carbureted applications, a returnless system with a traditional-style regulator (also called a "blocking style" regulator) does not circulate fuel back to the fuel tank with a return line. Fuel is pumped to the regulator, where pressure is reduced, and then continues to the carburetor, where flow is controlled by the floats and needle/seat assembly. With fuel-injected engines, a returnless fuel system does not have an external return line that brings fuel back to the fuel tank, directly from the external regulator or the fuel rails. Instead, fuel is recirculated inside the tank and pressure is controlled with an internal regulator, typically in factory fuel-injected vehicles.

How To Convert A Non Returnless Fuel System To A Return System

There are several ways to convert a non-returnless fuel system to a return fuel system, depending on how the fuel system is setup. For aftermarket and race applications, typically an external bypass fuel regulator is used, with a return line connecting it back to the top of the fuel tank. The (electric) fuel pump can be either inside the tank or outside the tank; mounted at or below the level of the bottom of the tank as close to it as possible. If using an aftermarket fuel injection, the fuel pressure regulator with return line can be mounted directly to one end of the fuel rail with the fuel supply on the other end or on the other fuel rail (in V6 & V8 applications for example) with the two fuel rails linked together. There are other ways to convert a non-return system to a return system, depending on if you have a factory setup or are putting aftermarket components together for a street rod or racecar. A JEGS expert is ready to answer your questions and help you build a return system for your application if needed.

Where Is The Fuel Pressure Regulator Located On A Returnless Fuel System?

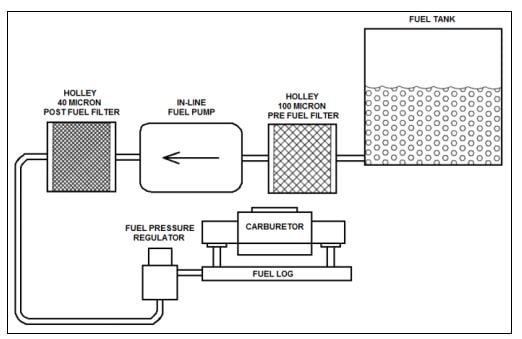

For factory fuel-injected vehicles, the pressure regulator is located inside the fuel tank on a returnless fuel system. In contrast, for return-style systems, the regulator is usually in the engine compartment near the fuel rails, with the return line from the rails or regulator routed back to the tank. In carburetor applications, the regulator is located in the engine compartment before the fuel filter and carburetor.

How To Hook Up A Carbureted Fuel Pressure Regulator With A Return Line

To connect a fuel pressure regulator with return line back to the fuel tank, the regulator needs to be a bypass regulator design. Next, connect the return line to the bypass fuel pressure regulator at the return or bypass port per the instructions, typically at the bottom. The other end of the return line connects to the top of the fuel tank. The feed from the gas tank enters the inlet of the regulator and exits to the carburetor fuel inlet to complete plumbing and installation.

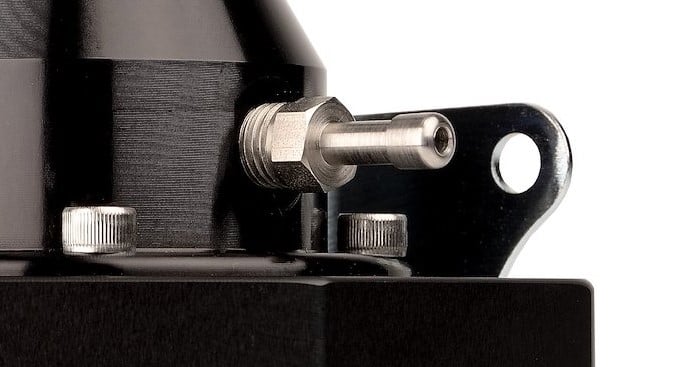

Vacuum Boost Reference

The vacuum or boost reference feature of a fuel pressure regulator is designed to compensate for changes in intake manifold vacuum or boost pressure, ensuring a consistent fuel pressure under varying engine load and throttle conditions. This feature allows the regulator to adjust the fuel pressure based on the engine's needs, taking into account factors such as changes in altitude, throttle position, and boost levels in forced induction systems. When the engine is under high vacuum conditions, such as during deceleration or idle, the regulator responds by reducing the fuel pressure to prevent excessive fuel flow. On the other hand, during moments of increased demand, such as wide-open throttle or high boost levels, the regulator compensates by raising the fuel pressure to provide the necessary fuel flow. By maintaining a steady fuel pressure, the vacuum or boost reference feature ensures consistent fuel delivery and helps optimize engine performance and responsiveness throughout the entire operating range.

Fuel Pressure Adjustment

Adjustable fuel pressure regulators offer the flexibility to fine-tune the fuel pressure according to the specific requirements of an engine. This adjustment capability allows for optimizing fuel delivery and achieving optimal engine performance. However, it is crucial to consult the manufacturer's instructions or seek manufacturer assistance when adjusting the fuel pressure. Each engine and fuel system may have different requirements, and improper adjustments can lead to suboptimal performance, fuel inefficiency, or even engine damage. Professional guidance ensures that the fuel pressure is adjusted within safe and optimal ranges, taking into account factors such as engine type, fuel delivery system, and desired performance goals. By following the recommended procedures and seeking expert advice, you can ensure that the fuel pressure is accurately adjusted to meet the specific needs of your engine.

Installation Considerations

When installing a fuel pressure regulator, several considerations should be taken into account to ensure proper functionality and reliability of the fuel system. First and foremost, the ideal placement of the fuel pressure regulator is typically between the fuel pump and the carburetor or fuel injection system. This allows for accurate fuel pressure regulation and control. It's important to use appropriate fittings and fuel lines that are compatible with the fuel system and can handle the pressure and flow requirements. Incorrect fittings or fuel lines may result in leaks or fuel system malfunctions. Additionally, it is crucial to verify the fuel pressure with a fuel pressure gauge after installation. This step ensures that the regulator is properly adjusted and maintaining the desired fuel pressure within the recommended range. Regular monitoring of the fuel pressure using a gauge is also recommended to identify any potential issues or fluctuations in pressure. By paying attention to these installation considerations, you can ensure a proper and effective fuel pressure regulator installation, promoting optimal fuel system performance and reliability.

Maintenance and Inspection

Regular maintenance and inspection of the fuel pressure regulator is essential for the proper functioning and longevity of the fuel system. It is recommended to periodically inspect the regulator for any signs of wear, leaks, or malfunctions. This includes checking for fuel leaks around the regulator or fuel lines, inspecting the diaphragm for any signs of damage or deterioration, and ensuring proper operation of the internal components. If the fuel pressure regulator fails to maintain the correct fuel pressure or shows any signs of malfunction, it is crucial to replace it promptly. A faulty regulator can result in inconsistent fuel pressure, which can negatively impact engine performance, fuel efficiency, and emissions control. By staying vigilant and addressing any issues with the fuel pressure regulator promptly, you can ensure the reliable and efficient operation of your fuel system.

Understanding the role and importance of a fuel pressure regulator in a fuel system is crucial for achieving optimal engine performance, fuel efficiency, and emissions control. By maintaining the correct fuel pressure, fuel atomization, combustion, and overall engine operation are optimized, resulting in improved power output and reduced fuel wastage. The fuel pressure regulator, along with its adjustable features and vacuum/boost reference capability, ensures consistent fuel pressure under varying engine load and throttle conditions. Proper installation, including the ideal placement of the regulator and the use of appropriate fittings and fuel lines, is essential for reliable and efficient operation. Regular maintenance and inspection of the regulator help identify any potential issues and ensure the longevity of the fuel system. By considering these factors and following manufacturer guidelines, you can harness the benefits of a properly functioning fuel pressure regulator, enhancing the performance and efficiency of your vehicle's fuel system.