Sign up now to join the JEGS email newsletter and be the first to learn about new products, special deals and e-mail only offers!

When it comes to improving a vehicle's performance, choosing the right differential gear ratio is crucial. But what is gear ratio, and how do you calculate it? In this article, we'll explore the basics of differential gear ratio and provide tips for choosing the correct one for your vehicle.

A differential gear ratio is the relation between the number of teeth on the ring gear and the number of teeth on the pinion gear. Inside the front or rear axle of a vehicle is a ring gear and pinion gear set. The pinion gear, which is the smaller of the two gears, is connected to the driveshaft by a universal joint, via a pinion yoke, spinning in the same direction. The larger ring gear is mounted perpendicular to the pinion gear and is mounted to the differential, so that it meshes with the pinion gear. The ring gear changes the direction of movement and power from the driveshaft to match the rotation of the wheels. The wheels are connected to the axle shafts, which are connected to the differential carrier the ring gear is bolted to.

Depending on the purpose of your vehicle, the ideal gear ratio needs to be determined. If the goal is to achieve maximum fuel efficiency for highway driving, top speed, or lower engine rpms at any given speed, a numerically lower gear ratio is needed. If maximum acceleration is desired a numerically higher differential gears ratio will be required. The more teeth on the pinion gear, the higher the top speed that can be achieved with the vehicle. However, the acceleration is going to be slower. Likewise, the less teeth on the pinion gear, the lower the top speed will be on the vehicle but the faster the acceleration will be. For the ring gear, the more teeth, the lower the top speed, but faster the acceleration will be achieved. Less ring gear teeth will result in higher top speed but slower acceleration. The gear ratio is calculated by taking the number of ring gear teeth and dividing it by the number of pinion gear teeth.

The gear ratio has a significant impact on a vehicle's acceleration and fuel efficiency. A (numerically) lower gear ratio, such as 3.08:1, will provide better fuel economy but slower acceleration than a gear ratio that is numerically higher. It will also allow a vehicle to reach a higher top speed. On the other hand, a (numerically) higher gear ratio, such as 4.56:1, will offer faster acceleration but with lower fuel efficiency.

If you're looking to improve acceleration, a numerically higher gear ratio is the way to go. This is because a higher gear ratio will provide more torque to the wheels, allowing the vehicle to accelerate faster. However, keep in mind that this will come at the expense of fuel efficiency and reduced top speed, since engine rpms will be higher at the same speed compared to a numerically lower gear ratio.

If fuel efficiency is your top priority, a numerically lower gear ratio is the better choice. This is because a lower gear ratio will allow the engine to operate at a lower RPM while maintaining a given speed. This results in better fuel economy and increased top speed, but slower acceleration.

Sign up now to join the JEGS email newsletter and be the first to learn about new products, special deals and e-mail only offers!

Ring Gear Teeth / Pinion Gear Teeth = Gear Ratio

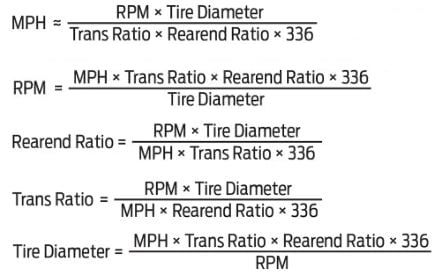

To calculate differential gear ratio, divide the ring gear tooth count by the pinion gear tooth count. For example, after counting, you have 41 ring gear (larger gear) teeth and 11 pinion gear (smaller gear) teeth. To calculate gear ratio, you will put into a calculator (if needed) 41 divided by 11. This equals 3.73. This combination provides an advertised “3.73 ratio”. If you are looking for the optimum gear ratio for the drag strip, you first need some information from the vehicle. Ideally, you want to race the vehicle at the dragstrip with the current ring and pinion setup as a base for comparison to determine the optimum ratio. The info needed includes the current gear differential ratio, tire diameter, engine rpms at the finish line, and the mph at the finish line (confirmed with the time slip). If the maximum RPM of your engine is reached (the rpm before engine power drops off, typically the top of the camshaft power band) right at the finish line, you have the correct gear ratio and do not need to change it. If you reached the maximum RPM before the finish line, the numerical gear ratio is too high and you need to reduce it. If you did not reach the maximum RPM at the finish line, the numerical gear ratio is too low and needs to be increased. If the optimum gear ratio is not available, find the closest one to it without reaching your maximum engine rpm to prevent possible engine damage. The use of a calculator or gear ratio formula will help you to figure out how to calculate gear ratio and which ring and pinion to use. To determine the gear ratio use the following formula:

RPM (at maximum engine power) x tire diameter / MPH x transmission ratio (this should be 1, unless in overdrive at the finish line) x 336 (336 is a constant value needed and represents inches per mile / Pi x minutes in an hour)

(leave blank for what you want to solve)

Solve For:

Gear Ratio:

Top Speed (in MPH):

Tire Size (in inches):

Engine RPM:

Having understood how gear ratio affects acceleration, top speed, and fuel mileage, what is the best ratio? First you need to determine if the primary goal is acceleration, top speed, or best fuel mileage. Next, you need to confirm your vehicle's measurements. There are three elements involved in determining the best gear ratio: engine rpms, vehicle speed, and tire diameter.

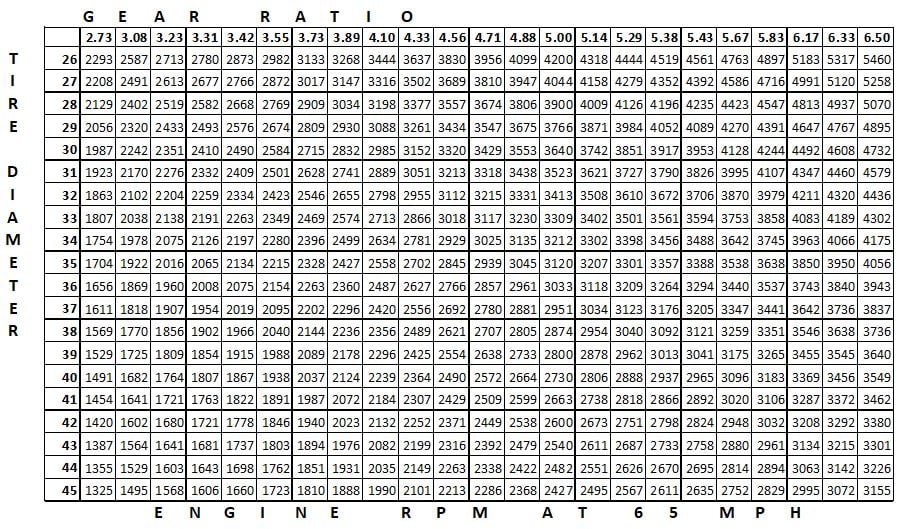

Below is a gear ratio chart showing what your engine RPMs would be at 65 MPH based on your tire diameter and differential gear ratio in third gear (1:1 transmission ratio). If you have overdrive, the rpm will be lower in that gear. It is important to use a gear ratio that will not lower engine rpm below your camshaft power band or torque converter stall speed (for automatic transmission applications) at cruise speed, which will cause poor engine performance and increased transmission temperature, leading to damage or even failure.

Below is the group of gear ratio formulas that will help you determine What either the vehicle MPH, engine RPM, differential gear ratio, transmission gear ratio, or tire diameter will be based on what you input for the other four specifications.

Choosing the correct differential gear ratio is essential to optimize your vehicle's performance. By understanding the basics of gear ratio and how to calculate it, you can make an informed decision that balances acceleration and fuel efficiency according to your priorities.